- 0800 056 0404

- 0191 386 5303

- sales@opuscnc.co.uk

- Units 22A-D Roeburn House, Mandale Business Park, Durham. DH1 1TH

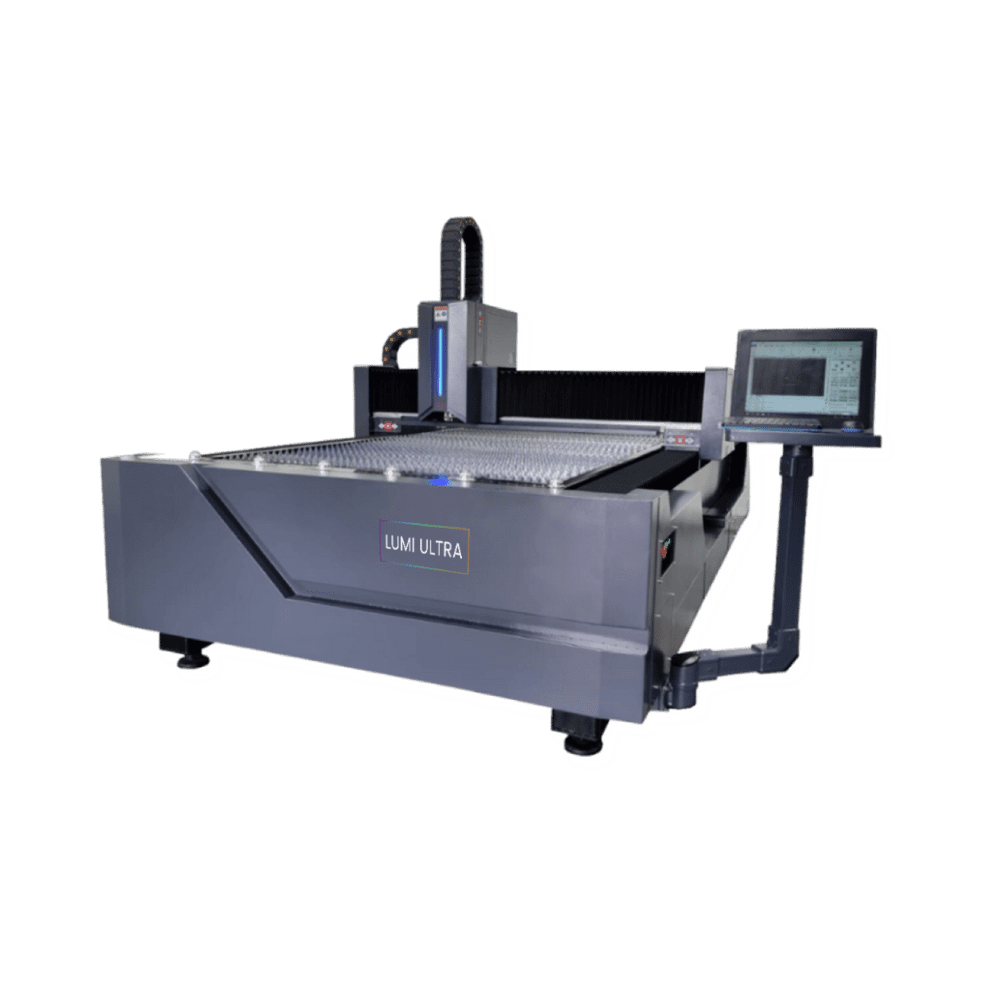

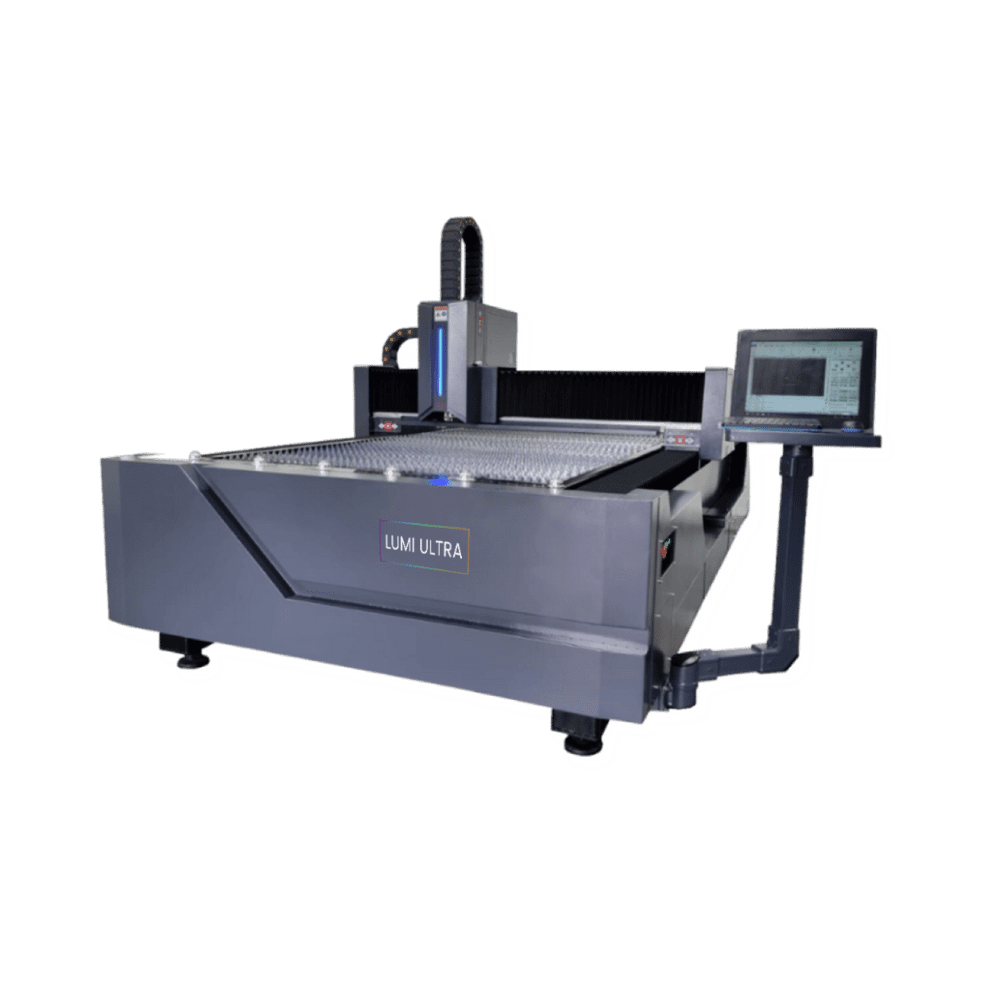

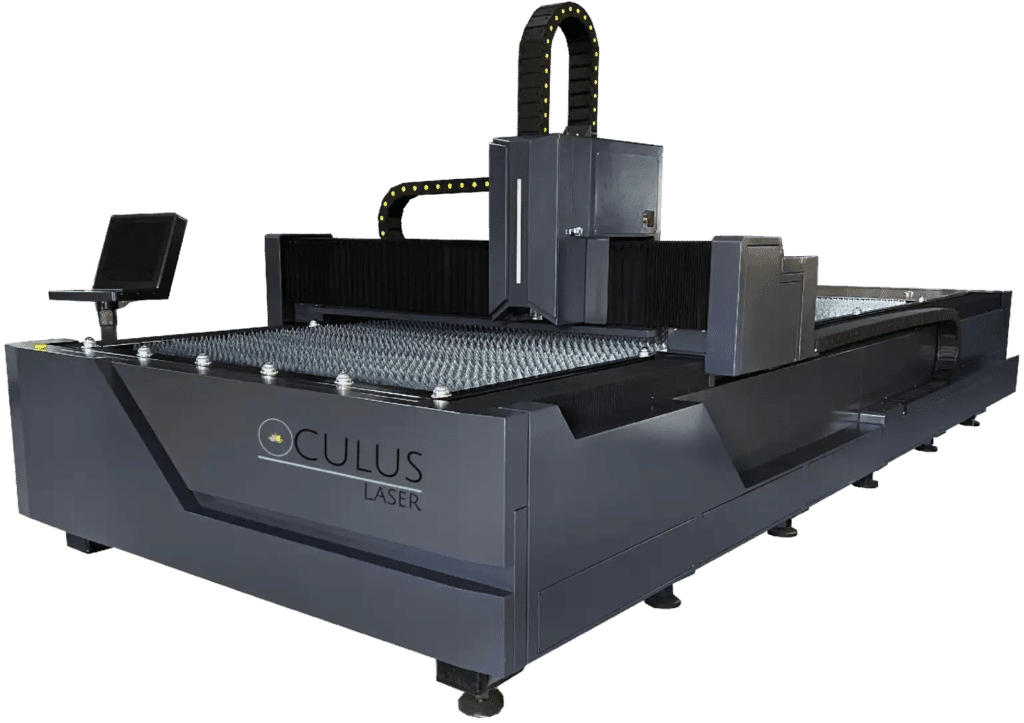

The Benefits of the Oculus Fibre Laser

The Oculus fibre lasers are ideal for cutting and engraving metallic material such as aluminium, stainless steel and mild steel. They make use of optical fibre cable to guide light, generating a beam that is often more precise and targetable than other methods.

Engraving

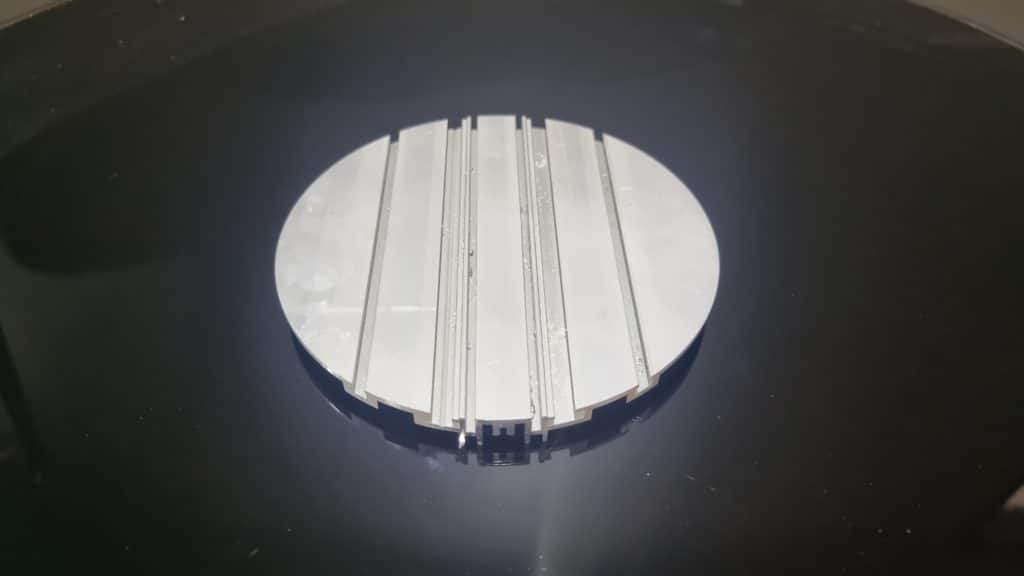

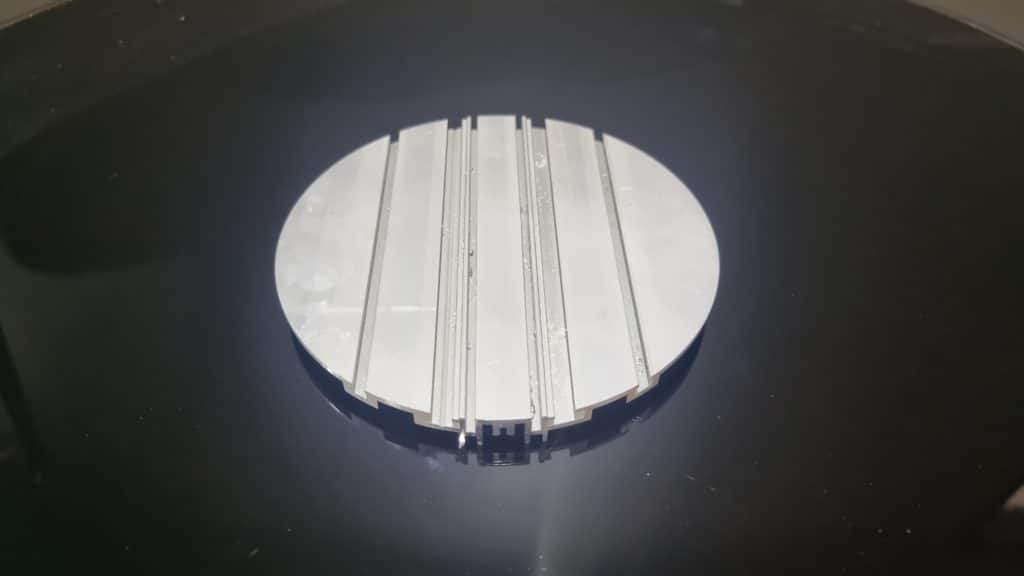

Fibre lasers perform engravings by removing a small amount of surface material from a substrate, according to a pattern described by a computer programme. The laser has a similar action to a chisel, but unlike conventional tools, offers a far more accurate cut, allowing for more intricate designs

Marking

Manufacturers also sometimes use fibre lasers for marking. This process involves using intense pulsed beams to create marks on the surface of materials to produce visible discolouration. Common applications include creating indelible serial numbers or barcodes on products.

Drilling

Focused fibre lasers can create percussion-drilled holes in substrates, such as aluminium and steel. The intense heat generated by lasers vaporises material at the targeted site, giving manufacturers the ability to carve multiple tiny holes in close proximity to the material’s surface.

Engraving

Marking

Drilling

Fibre lasers perform engravings by removing a small amount of surface material from a substrate, according to a pattern described by a computer programme. The laser has a similar action to a chisel, but unlike conventional tools, offers a far more accurate cut, allowing for more intricate designs

Manufacturers also sometimes use fibre lasers for marking. This process involves using intense pulsed beams to create marks on the surface of materials to produce visible discolouration. Common applications include creating indelible serial numbers or barcodes on products.

Focused fibre lasers can create percussion-drilled holes in substrates, such as aluminium and steel. The intense heat generated by lasers vaporises material at the targeted site, giving manufacturers the ability to carve multiple tiny holes in close proximity to the material’s surface.

Fibre Laser Pros:

Fibre Laser Pros:

- Decreased production timescales

- Greater accuracy and precision

- More efficiency with reduced energy bills

- Less consumable parts giving more reliability

- Minimal house-keeping

- The ability to cut reflective materials

- Higher productivity – lower operational costs offer a greater return on your investment.

Fibre Laser Pros:

- Decreased production timescales

- Greater accuracy and precision

- More efficiency with reduced energy bills

- Less consumable parts giving more reliability

- Minimal house-keeping

- The ability to cut reflective materials

- Higher productivity – lower operational costs offer a greater return on your investment.