- 0800 056 0404

- 0191 386 5303

- sales@opuscnc.co.uk

- Units 22A-D Roeburn House, Mandale Business Park, Durham. DH1 1TH

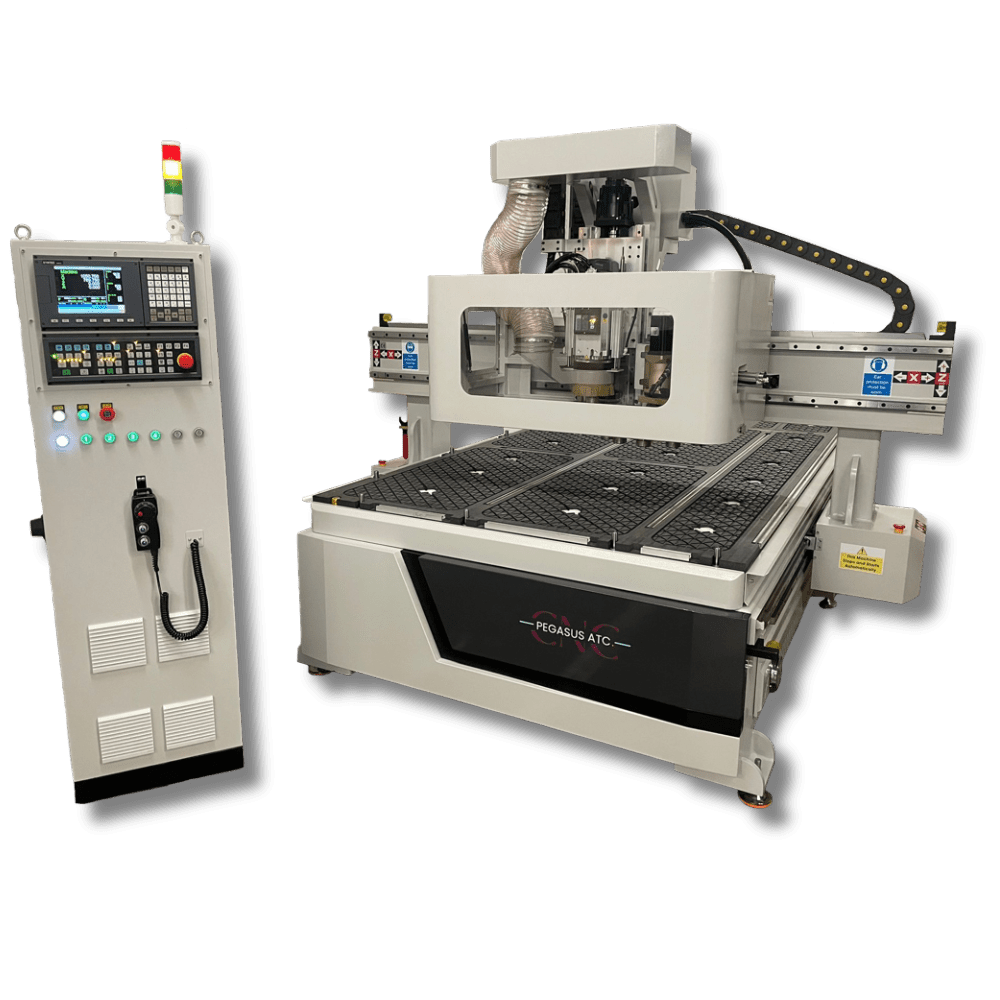

PEGASUS ATC

CNC ROUTER

Ultra-Spec Automatic Tool Change CNC Router

The Pegasus ATC (Automatic Tool Change) CNC router stands out as a high-performance CNC machine, boasting advanced features, components, and capabilities that significantly improve its precision, efficiency, and versatility.

Equipped with top-tier components like the Italian HSD spindle, Japanese servo motors and drives, and the comprehensive Syntec control system, it offers exceptional value without the steep cost of similar high-end brands.

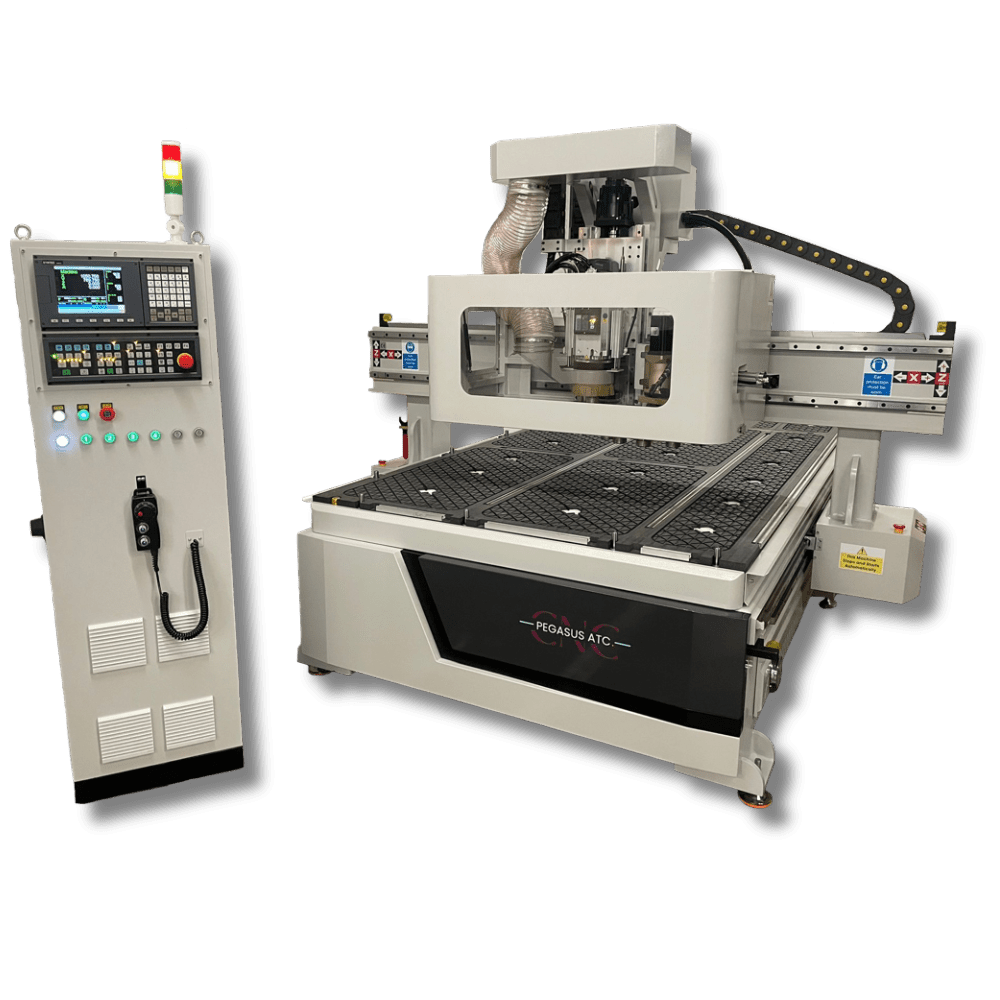

PEGASUS ATC

CNC ROUTER

Ultra-Spec Automatic Tool Change CNC Router

The Pegasus ATC (Automatic Tool Change) CNC router stands out as a high-performance CNC machine, boasting advanced features, components, and capabilities that significantly improve its precision, efficiency, and versatility.

Equipped with top-tier components like the Italian HSD spindle, Japanese servo motors and drives, and the comprehensive Syntec control system, it offers exceptional value without the steep cost of similar high-end brands.

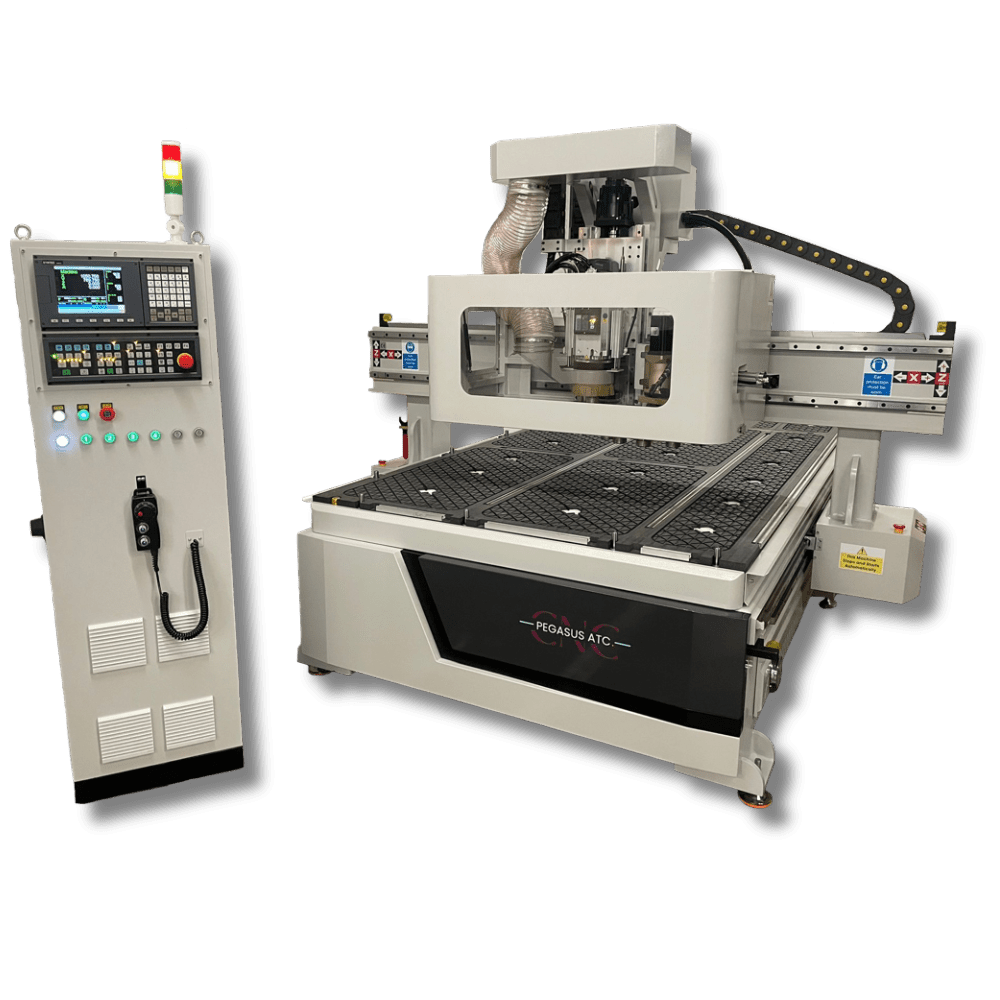

PEGASUS ATC

CNC ROUTER

Ultra-Spec Automatic Tool Change CNC Router

The Pegasus ATC (Automatic Tool Change) CNC router stands out as a high-performance CNC machine, boasting advanced features, components, and capabilities that significantly improve its precision, efficiency, and versatility.

Equipped with top-tier components like the Italian HSD spindle, Japanese servo motors and drives, and the comprehensive Syntec control system, it offers exceptional value without the steep cost of similar high-end brands.

PEGASUS ATC

CNC ROUTER

Ultra-Spec Automatic Tool Change CNC Router

The Pegasus ATC (Automatic Tool Change) CNC router stands out as a high-performance CNC machine, boasting advanced features, components, and capabilities that significantly improve its precision, efficiency, and versatility.

Equipped with top-tier components like the Italian HSD spindle, Japanese servo motors and drives, and the comprehensive Syntec control system, it offers exceptional value without the steep cost of similar high-end brands.

PEGASUS ATC KEY FEATURES

Overview

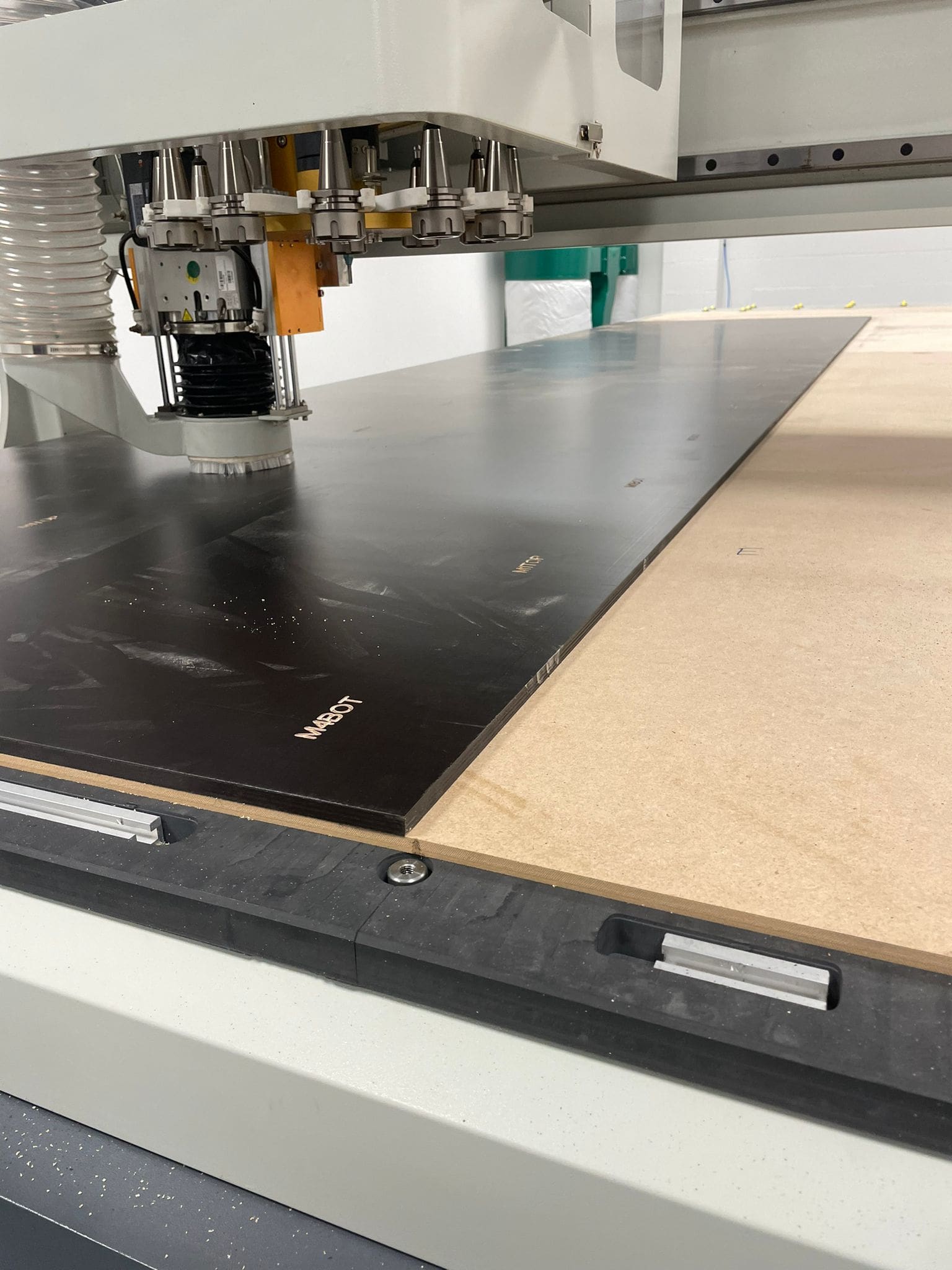

Automatic Tool Change

Comprising of 12 x ISO 30 tools, the Pegasus ATC CNC router offers the user quick tool changes on a carousel system, without the need for manual intervention.

Japanese Servo Drives

Only found on high-spec CNC machines, the Pegasus comes as standard with Japanese Yaskawa servo motors and drives, for superior performance and smoothness.

Italian 9kW HSD Spindle

Another industry-leading componenet only found on superior CNC routers is the Italian 9kW HSD spindle. We supply the latest model ES951, on all Pegasus ATC CNC machines.

7.5kW Extraction System

With 7.5kW of power, the extraction system can efficiently remove large volumes of dust, chips, and other particles from the cutting area. This is essential for maintaining a clean workspace and preventing material buildup around the tool and workpiece.

Dual Stage Vacuums

We include up to 4 x 7.5kW dual-stage, 3 phase vacuum pumps as standard on all of the Pegasus ATC CNC routers.

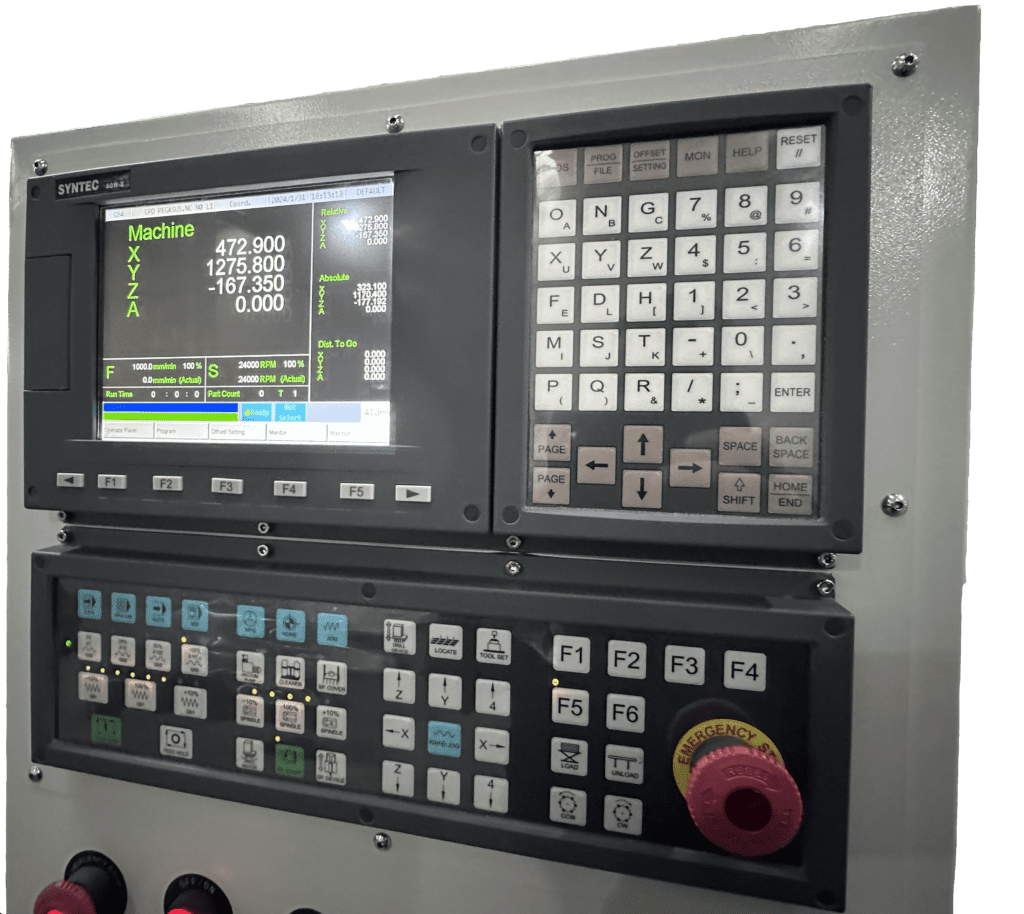

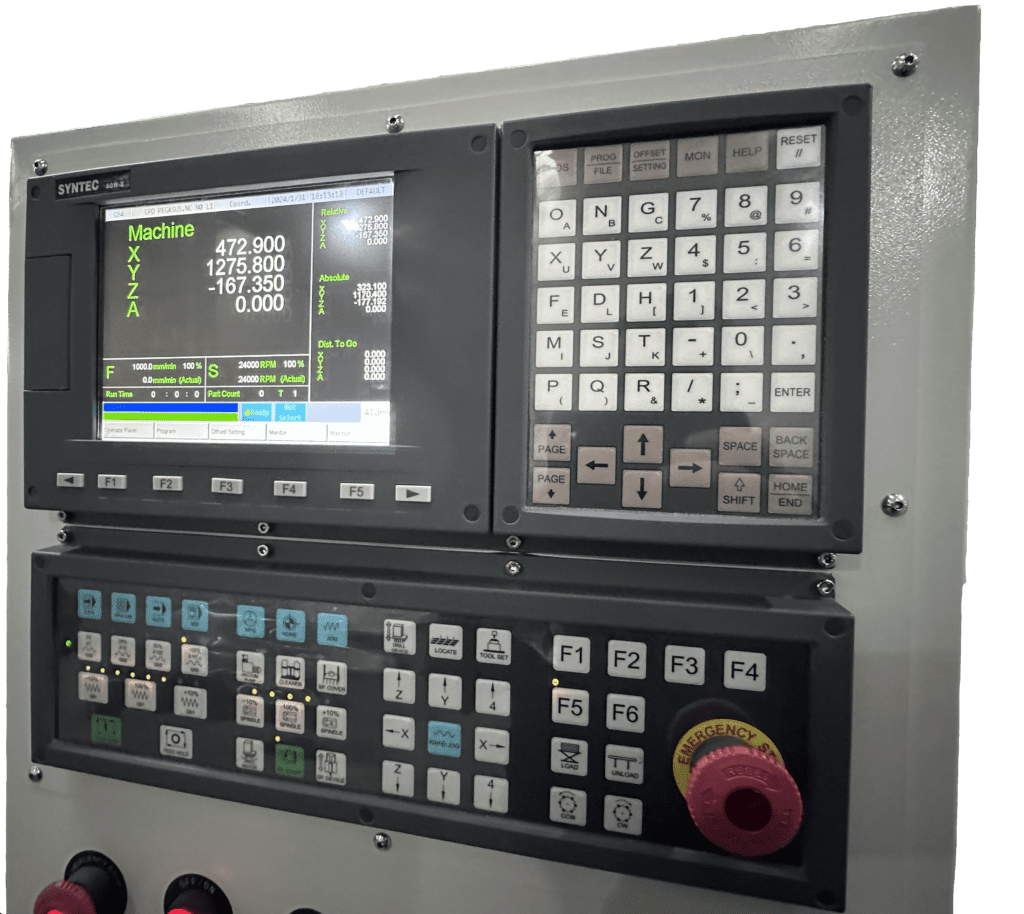

Syntec Control system

The Syntec controller is highly regarded for its robust performance, user-friendly interface, and advanced features that enhance CNC machine operations. It offers reliable precision and control, supporting complex machining tasks with ease due to its powerful processing capabilities and compatibility with various software.

Unique Matrix Bed

Designed by Opus CNC, the enhanced zoned bed gives full suction throughout, unlike standard CNCs.

Separate Control Box

The control box is separate from the Pegasus CNC machine, so it is less exposed to dust, debris, vibrations, and heat generated during machining. This minimises the risk of electrical component failure.

Warranty

We offer 2 years full parts and labour warranty with all Pegasus ATC CNC machines. This longer warranty period shows we have greater confidence in our Pegasus ATC CNC’s durability and quality.

Delivery

Depending on the size, your Pegasus ATC CNC router will be delivered by a curtain side lorry, which will require a forklift. Alternatively, delivery can be made by a HIAB, with a crane.

Installation

One of the Opus engineers will carry out the full installation. All Opus engineers are experienced and go through vigorous in-house training programs throughout their Opus careers.

Training

Machine and software training is fully inclusive with the Pegasus ATC CNC and is divided into three sections: machine operation, software, and safety. We customise all training to match individual capabilities.

Models

Pegasus 1313 ATC CNC Router

Working Area: 1300 x 1300mm

Dimensions: L2170 x W2246

9kW Italian HSD Spindle

Carousel Automatic Tool Change

12 ISO Tool Holders Included

Gantry Clearance: 300mm

Vacuum Pump: 7.5kW

Syntec Control System

Yaskawa Servo Motors & Drives

Material Locating Pins Included

Bearing Wipers

Networkable

7.5kW Extraction System

Weight 2,400kg

Pegasus 1325 ATC CNC Router

Working Area: 1300 x 2500mm

Dimensions: L3370 x W2246

9kW Italian HSD Spindle

Carousel Automatic Tool Change

12 ISO Tool Holders Included

Gantry Clearance: 300mm

Vacuum Pump: 7.5kW

Syntec Control System

Yaskawa Servo Motors & Drives

Material Locating Pins Included

Bearing Wipers

Networkable

7.5kW Extraction System

Weight 2,500kg

Pegasus 1530 ATC CNC Router

Working Area: 1525 x 3050mm

Dimensions: L3870 x W2446

9kW Italian HSD Spindle

Carousel Automatic Tool Change

12 ISO Tool Holders Included

Gantry Clearance: 300mm

Vacuum Pump: 5.5kW x 2

Syntec Control System

Yaskawa Servo Motors & Drives

Material Locating Pins Included

Bearing Wipers

Networkable

7.5kW Extraction System

Weight 2,600kg

Pegasus 2030 ATC CNC Router

Working Area: 2100 x 3050mm

Dimensions: L3910 x W3066

9kW Italian HSD Spindle

Carousel Automatic Tool Change

12 ISO Tool Holders Included

Gantry Clearance: 300mm

Vacuum Pump: 7.5kW x 2

Syntec Control System

Yaskawa Servo Motors & Drives

Material Locating Pins Included

Bearing Wipers

Networkable

7.5kW Extraction System

Weight 2,700kg

Pegasus 2040 ATC CNC Router

Working Area: 2000 x 4000mm

Dimensions: L4910 x W3066

9kW Italian HSD Spindle

Carousel Automatic Tool Change

12 ISO Tool Holders Included

Gantry Clearance: 300mm

Vacuum Pump: 7.5kW x 2

Syntec Control System

Yaskawa Servo Motors & Drives

Material Locating Pins Included

Bearing Wipers

Networkable

7.5kW Extraction System

Weight 2,800kg

Pegasus 2060 ATC CNC Router

Working Area: 2000 x 6000mm

Dimensions: L6910 x W3066

9kW Italian HSD Spindle

Carousel Automatic Tool Change

12 ISO Tool Holders Included

Gantry Clearance: 300mm

Vacuum Pump: 7.5kW x 2

Syntec Control System

Yaskawa Servo Motors & Drives

Material Locating Pins Included

Bearing Wipers

Networkable

7.5kW Extraction System

Weight 3,000kg

The benefits of a carousel automatic tool change

Carousel tool changers are typically faster than linear ones because they rotate directly to the needed tool’s position. This reduces the time required to switch tools, improving overall production efficiency, especially when handling multiple tools in one job.

Also, as the carousel rotates to select the required tool, it ensures that the next tool is always within reach of the spindle. This minimises downtime between tool changes and keeps the workflow smooth and continuous.

The carousel tool changers on the Pegasus model are mounted closer to the spindle, reducing the distance the Pegasus has to travel to pick up or swap tools. This improves the overall performance and responsiveness. Our carousel design allows the Italian HSD spindle to reach the next tool with minimal movement, which certainly reduces time between tool changes. This is especially advantageous when using many tools in quick succession.

The benefits of a carousel automatic tool change

Carousel tool changers are typically faster than linear ones because they rotate directly to the needed tool’s position. This reduces the time required to switch tools, improving overall production efficiency, especially when handling multiple tools in one job.

Also, as the carousel rotates to select the required tool, it ensures that the next tool is always within reach of the spindle. This minimises downtime between tool changes and keeps the workflow smooth and continuous.

The carousel tool changers on the Pegasus model are mounted closer to the spindle, reducing the distance the Pegasus has to travel to pick up or swap tools. This improves the overall performance and responsiveness. Our carousel design allows the Italian HSD spindle to reach the next tool with minimal movement, which certainly reduces time between tool changes. This is especially advantageous when using many tools in quick succession.

Syntec Control System

Improved Precision

The Syntec control system has a reputation for exceptional precision, allowing for highly accurate cuts and precise movements of the router. This is particularly important for complex designs or intricate shapes where precision is critical.

Advanced Functionality

There are a range of advanced features, such as automatic tool changers, multiple axes control, and real-time monitoring, which improve the performance and functionality of the Pegasus ATC CNC router.

Tool Wear Compensation

Indeed, the Syntec controller offers built-in tool wear compensation functions, allowing users to manually or automatically adjust the tool path to account for wear. As the tool wears down over time, the system modifies the cutting depth or adjust offsets to maintain precision without requiring a physical tool change.

Syntec Control System

Improved Precision

The Syntec control system has a reputation for exceptional precision, allowing for highly accurate cuts and precise movements of the router. This is particularly important for complex designs or intricate shapes where precision is critical.

Advanced Functionality

There are a range of advanced features, such as automatic tool changers, multiple axes control, and real-time monitoring, which improve the performance and functionality of the Pegasus ATC CNC router.

Tool Wear Compensation

Indeed, the Syntec controller offers built-in tool wear compensation functions, allowing users to manually or automatically adjust the tool path to account for wear. As the tool wears down over time, the system modifies the cutting depth or adjust offsets to maintain precision without requiring a physical tool change.

Want to see more?

Check Out The Pegasus ATC CNC in Action Below!

Request A Quotation

Want to join our long list of satisfied customers? Then, why not fill in the form to receive a no-obligation quotation from one of our experienced engineers?

Don’t worry, we won’t hassle any potential customer! All the Opus team are engineers, not sales-people!

Want to join our long list of satisfied customers? Then, why not fill in the form below to receive a no-obligation quotation from one of our experienced engineers?

Don’t worry, we won’t hassle any potential customer! All the Opus team are engineers, not sales-people!

Queries & Answers

Is Opus a UK company?

Yes, we are based in the North East of England and we have an extensive team of engineers who work throughout the whole of the UK, including an engineer who is based in Northern Ireland.

What software is supplied?

VCarve Pro software is supplied as standard with all Pegasus ATC CNC machines. VCarve Pro can be upgraded to Aspire for all those 3D machining.

We are proud partners of Cadspec who specialise in many suitable CNC software such as Fusion 360 and Autodesk.

We can also supply post-processors for Fusion 360 and Rhinocam if required.

Is training included?

Certainly! With a proven track record of transforming individuals into experts, our engineers are a beacon of excellence in CNCs and skill development. You will receive machine training, safety management and VCarve Pro software training. Our engineers adeptly customise their training approach to align perfectly with your requirements and proficiencies!

Additionally, all Opus engineers are fully trained in Fusion 360 and can supply training in place of VCarve when necessary.

Is tooling supplied?

Understanding that each customer has unique tooling requirements, our provision of tooling is primarily geared towards the training process only. Nevertheless, we work in partnership with the established tooling supplier Cutting Edge Carbide, and we can work with you for all your tooling needs.

Do I need 3-phase electric supply?

Pegasus ATC CNC routers come equipped with a 3-phase connectivity setup. We can however, produce the Pegasus ATC CNC machine with a single-phase configuration. It is worth noting, modifying to single-phase will entail replacing certain components with single-phase counterparts, such as the spindle, vacuum pumps, inverter, and extraction system.

What bed sizes are available?

We offer the following standard sizes, 1300x1300mm, 1300x2500mm, 1525x3050mm, 2100x3050mm, 2000x4000mm and 2000x6000mm. We also manufacture bespoke sized Pegasus ATC CNC routers. Please ask one of the team if you need a bed size which isn’t mentioned above.

SPREAD THE COST

We understand how vital cash flow can be, which is why we work with leading asset finance provider Anglo Scottish Asset Finance who offer competitive business finance across the UK.

PEGASUS GALLERY

Check out our most recent Pegasus ATC CNC Router installations!

RELATED MODELS

Olympus

CNC Router

Tool Change Type: Manual Tool Change

Spindle: 6kW Air-cooled Spindle

Drives: Stepper Drives

Motors: Stepper Motors

Control System: DSP Hand Controller

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 3.0kW Extraction System Included

Software Included: VCarve Pro

Delivery: Included

Installation: Included

Training: Included

Upgrades Available: PC Control System.

Prices from £10,995 plus VAT

Olympus PRO

CNC Router

Tool Change Type: Manual

Spindle: 9kW HQD Spindle

Drives: Delta Servo Drives

Motors: Delta Servo Motors

Control System: Opus PRO Hand Controller

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 5.5kW Extraction System Included

Software Included: VCarve Pro

Delivery: Included

Installation: Included

Training: Machine and Software Training Included

Upgrades Available: PC Control System | ATC

Prices from £15,495 plus VAT

Olympus ATC

CNC Router

Tool Change Type: Linear 8 x ISO 30 Tools/Automatic Tool Change

Spindle: 9kW HQD Spindle

Drives: Servo Drives

Motors: Servo Motors

Control: Opus PRO Control System

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 5.5kW Extraction System Included

Extras: Material Locating Pins

Software Included: VCarve Pro

Delivery & Installation: Included

Training: Machine and Software Training Included

Prices from £16,995 plus VAT

Trusted By