- 0800 056 0404

- 0191 386 5303

- sales@opuscnc.co.uk

- Units 22A-D Roeburn House, Mandale Business Park, Durham. DH1 1TH

THE HOME OF CO₂ & FIBRE

LASER CUTTERS

At Opus, we have a wide range of laser cutters, from the compact entry-level Oculus CO₂ Benchtop laser to the powerful, high-specification metal-cutting Lumi ULTRA fibre laser.

THE HOME OF

FIBRE & CO₂ LASER MACHINES

At Opus, we have a range of laser cutters, from the compact entry-level Oculus CO₂ Benchtop laser to the powerful, high-specification metal-cutting Lumi ULTRA fibre laser.

THE HOME OF

FIBRE & CO₂ LASER MACHINES

Industrial laser cutters for every application!

At Opus, we have a range of laser cutters, from the compact entry-level Oculus CO₂ Benchtop laser to the powerful, high-specification metal-cutting Lumi ULTRA fibre laser.

Lumi Fibre Lasers

Lumi Marker Fibre Laser

Power Source: Raycus

Laser Head: Raycus

Control System: EZCAD

Power: 30w or 50w

Red Dot: Ultra-precise

Tracing Assist: Yes

Foot Swtich: Yes

PC Computer: On-board

Networkable: Yes

Prices from £4,200 plus VAT

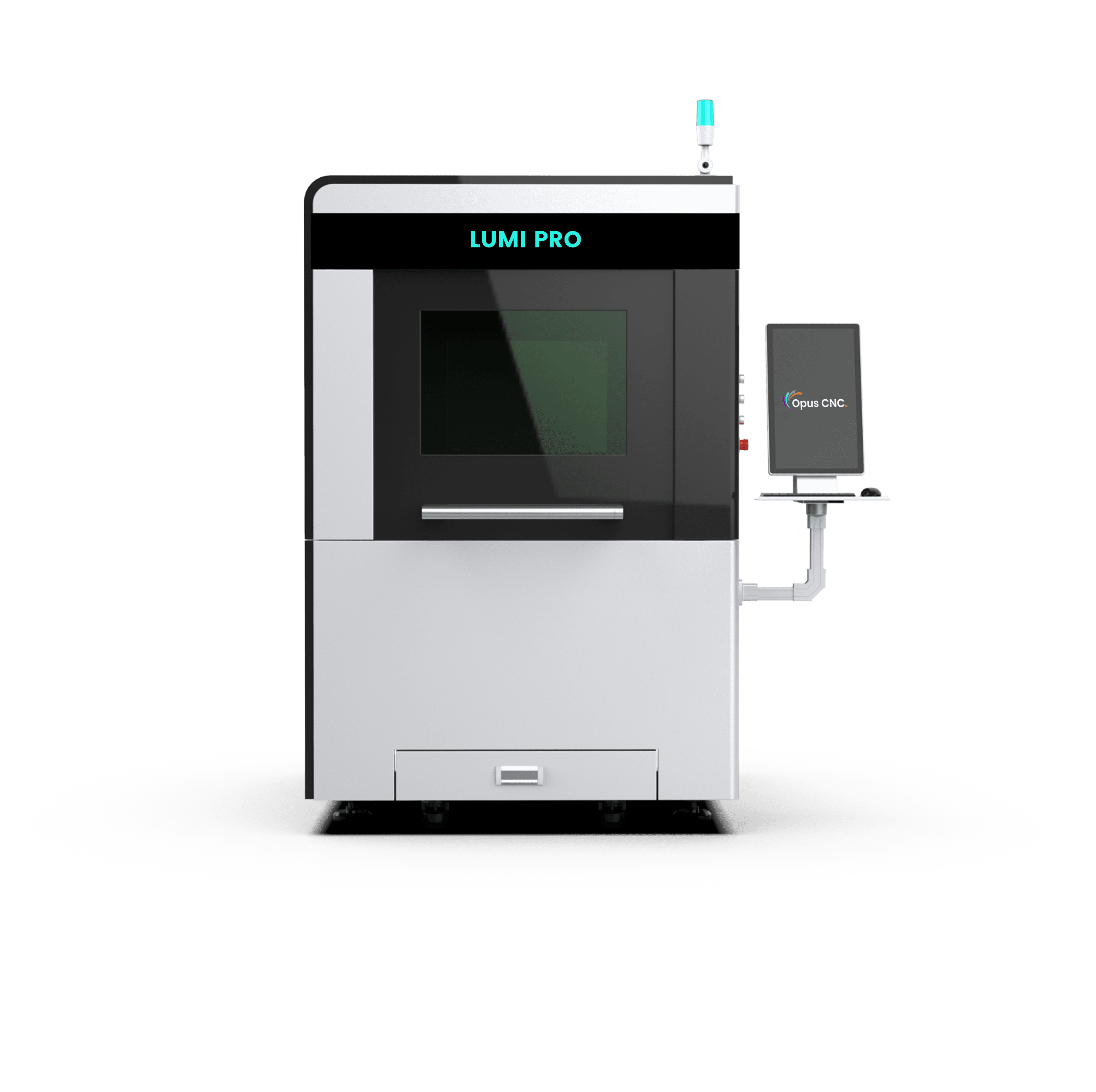

Lumi PRO Fibre Laser

Power Source: Max

Laser Head: Raytools

Control System: CypCut

Bed: Blade

Motors: Japanese Servo Motors

Red Dot: Ultra-precise

PC Computer: On-board

Auto Squaring: Inclusive

Networkable: Yes

Prices from £21,500 plus VAT

Lumi ULTRA Fibre Laser

Power Source: Raycus or Max

Laser Head: Raytools

Control System: CypCut

Bed: Blade

Motors: Yaskawa Servo Motors

Red Dot: Ultra-precise

PC Computer: On-board

Auto Squaring: Inclusive

Networkable: Yes

Prices from £30,000 plus VAT

Oculus CO₂ Lasers

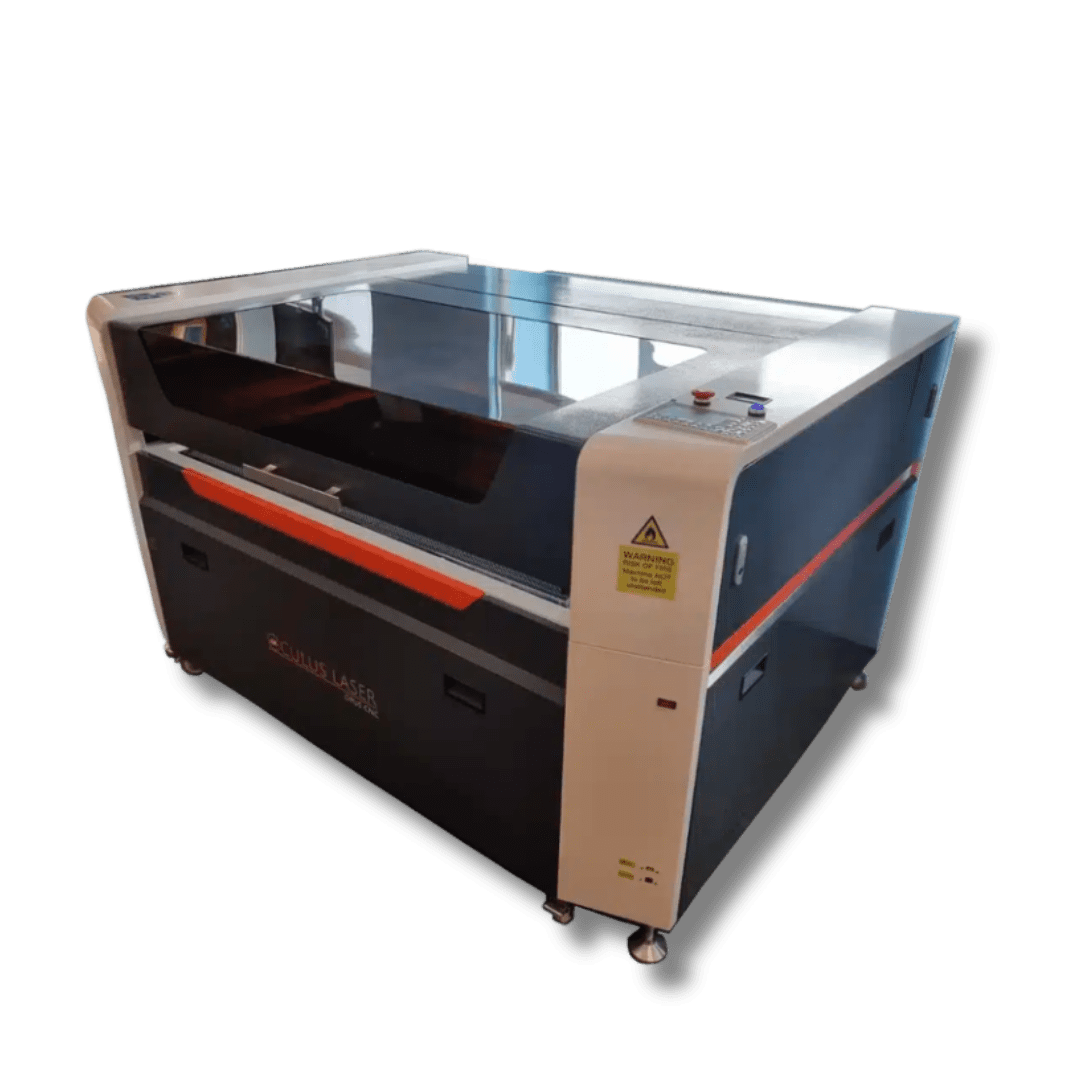

Oculus CO₂ Flatbed Laser

Power: 100w, 130w or 150w

Laser Source: CO₂

Table Type: Honeycomb & Blade

Motors: Stepper Motors

Red Dot: Included

Bed: Motorised up/down

Air Assist: Included

Extraction: Dual Extractions/Internal

Fits through a doorway: No

Prices from £13,000 plus VAT

Oculus CO₂ Free-Standing Laser

Power: 100w, 130w or 150w

Laser Source: CO₂

Table Type: Honeycomb & Blade

Motors: Stepper Motors

Red Dot: Included

Bed: Motorised up/down

Air Assist: Included

Extraction: External

Fits through a doorway: No

Prices from £6,000 plus VAT

Oculus CO₂ Benchtop Laser

Power: 80w

Laser Source: CO₂

Table Type: Honeycomb & Blade

Motors: Stepper Motors

Red Dot: Included

Bed: Motorised up/down

Air Assist: Included

Extraction: In-built

Fits through a doorway: Yes

Prices from £5,500 plus VAT

Discover Our Laser Range

Designed in the UK, all Opus laser cutting machines are suitable for many industries, from arts and crafts, to high-scale metal fabrication.

All Opus laser machines are fully tested by our Durham team and are CE certified.

When you purchase an Opus laser you will receive full delivery, installation and training. Once the installation has taken place, you will also receive up to 2 years warranty (depending upon model), lifetime telephone and email support and access to our customer portal.

Designed in the UK, all Opus laser cutting machines are suitable for many industries, from arts and crafts, to high-scale metal fabrication.

All Opus laser machines are fully tested by our Durham team and are CE certified.

When you purchase an Opus laser you will receive full delivery, installation and training. Once the installation has taken place, you will also receive up to 2 years warranty (depending upon model), lifetime telephone and email support and access to our customer portal.

Software Options

All of Opus lasers include control and design software. Depending upon model, we have a choice of either RDWorks, Lightburn or for our fibre lasers, we have CpyCut. Check out below for further information on each one individually.

RDWorks

Windows based RDWorks is a popular laser control software, especially valued for its accessibility and robust functionality. It is easy to navigate, making it suitable for both beginners and experienced users. The software simplifies the process of designing, editing, and managing laser cutting and engraving tasks.

RDWorks supports various file formats like DXF, AI, PLT, and BMP, making it versatile and compatible with different design software such as CorelDraw and Photoshop.

Lightburn

Lightburn is compatible with Windows, macOS, and Linux operating systems, making it accessible across a wide range of devices.

Included with LightBurn are built-in vector editing tools, allowing users to create and modify designs directly in the software, without needing external design programs.

It also has advanced features like path optimisation, auto-nesting, and cut simulation, helping users save time and reduce material waste.

CypCut

CypCut is a highly regarded laser cutting software known for its ease of use, powerful features, and robust performance, making it ideal for Lumi fibre laser machines.

One of its key strengths is its intuitive interface, which allows users, even those with minimal experience, to quickly and efficiently design, edit, and execute cutting jobs. The software is equipped with advanced nesting capabilities, which optimise material usage by automatically arranging parts to minimise waste.

Do I need a filtration system?

All Oculus lasers can extract externally (similiar to a tumble-dryer hose). However, we know this isn’t always ideal, such as classroom environments. We work in partnership with Donaldson BOFA International to supply outstanding filtration units for all of our CO₂ laser cutting machines that connect directly.

AD 350

Fume extraction system for light-duty laser marking, coding and engraving applications. The compact AD 350 is ideal for use in schools, sign-making workshops and small-scale industrial environments.

Suitable for Models 5030 and 6040

AD 500 iQ

The AD 500 iQ mid to high-end laser fume extraction system combines extremely large filter capacity with high airflow and pressure rates, making it the ideal choice for heavy-duty applications that generate large amounts of particulate and gaseous organic compounds.

Suitable for Models 6090, & 1390

AD 1000 iQ

High-performance laser fume extraction system for applications in laser marking, coding and engraving. The AD 1000 iQ high-end laser extraction system combines extremely large filter capacity with high airflow and pressure rates.

Suitable for Models 1610 & 1512

AD 2000 iQ

The AD 2000 iQ’s technology helps to deliver superior and measurable performance, helping to ensure airflow and filtration is maintained even when particulates start to build up.

Suitable for Models 1325 & 1525

Do I need a filtration system?

All Oculus lasers can extract externally (similiar to a tumble-dryer hose). However, we know this isn’t always ideal, such as classroom environments. We work in partnership with Donaldson BOFA International to supply outstanding filtration units for all of our CO₂ laser cutting machines that connect directly.

AD 350

Fume extraction system for light-duty laser marking, coding and engraving applications. The compact AD 350 is ideal for use in schools, sign-making workshops and small-scale industrial environments.

Suitable for Models 5030 and 6040

AD 500 iQ

The AD 500 iQ mid to high-end laser fume extraction system combines extremely large filter capacity with high airflow and pressure rates, making it the ideal choice for heavy-duty applications that generate large amounts of particulate and gaseous organic compounds.

Suitable for Models 6090, & 1390

AD 1000 iQ

High-performance laser fume extraction system for applications in laser marking, coding and engraving. The AD 1000 iQ high-end laser extraction system combines extremely large filter capacity with high airflow and pressure rates.

Suitable for Models 1610 & 1812

AD 2000 iQ

The AD 2000 iQ’s technology helps to deliver superior and measurable performance, helping to ensure airflow and filtration is maintained even when particulates start to build up.

Suitable for Models 1325 & 1525

AD 350

Fume extraction system for light-duty laser marking, coding and engraving applications. The compact AD 350 is ideal for use in schools, sign-making workshops and small-scale industrial environments.

Suitable for Models 5030 and 6040

AD 500 iQ

The AD 500 iQ mid to high-end laser fume extraction system combines extremely large filter capacity with high airflow and pressure rates, making it the ideal choice for heavy-duty applications that generate large amounts of particulate and gaseous organic compounds.

Suitable for Models 6090, & 1390

AD 1000 iQ

High-performance laser fume extraction system for applications in laser marking, coding and engraving. The AD 1000 iQ high-end laser extraction system combines extremely large filter capacity with high airflow and pressure rates.

Suitable for Models 1610 & 1812

AD 2000 iQ

The AD 2000 iQ’s technology helps to deliver superior and measurable performance, helping to ensure airflow and filtration is maintained even when particulates start to build up.

Suitable for Models 1325 & 1525

Trusted By