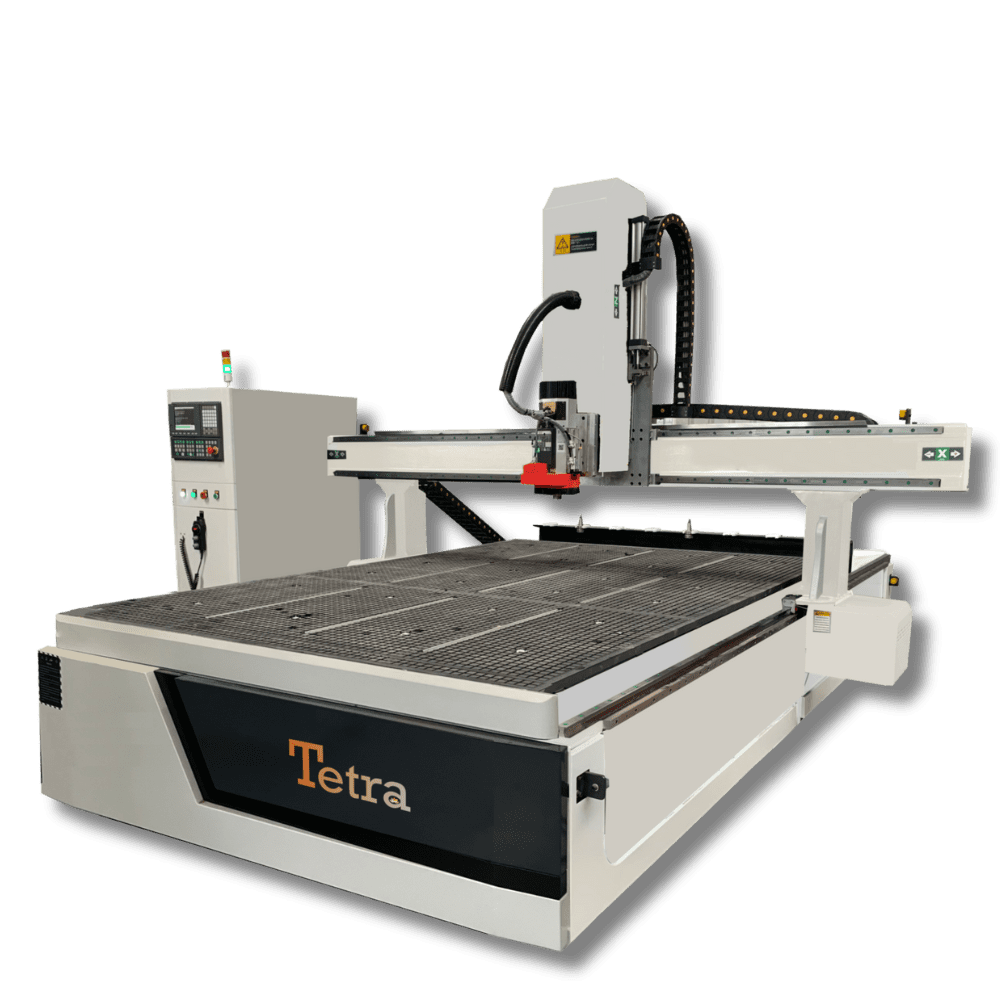

WHAT DEFINES A 4 AXIS?

The Tetra 4-axis CNC routing machine can move the cutting tool or workpiece in four distinct axes of motion. While traditional three-axis CNC machines can move along the X, Y, and Z axes, the Tetra 4-axis CNC machine adds a rotary or angular axis, typically known as the A axis or C axis.