- 0800 056 0404

- 0191 386 5303

- sales@opuscnc.co.uk

- Units 22A-D Roeburn House, Mandale Business Park, Durham. DH1 1TH

The Ultimate Guide to the Best

CNC Router in the UK

Introduction

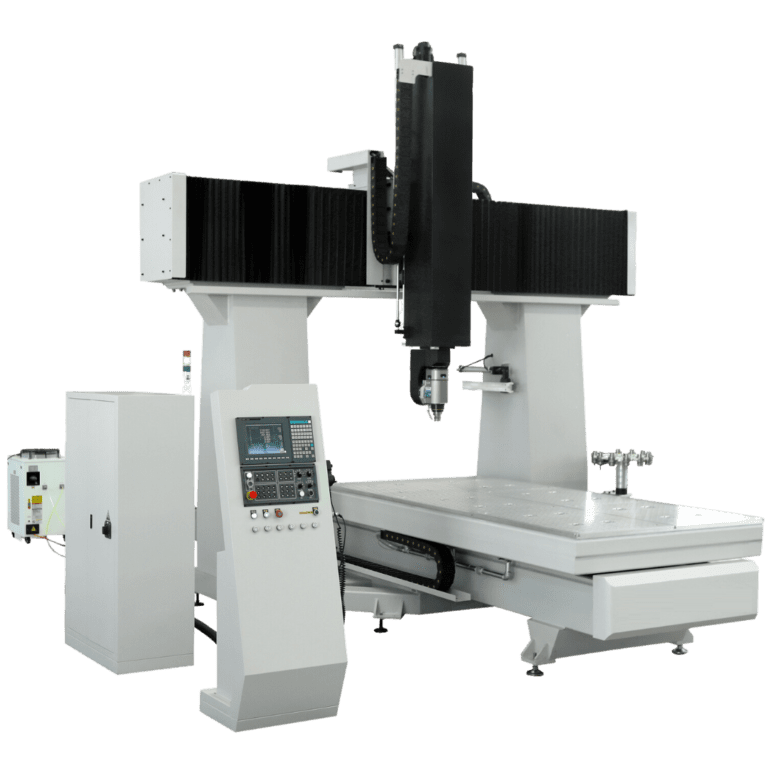

In the vibrant world of modern manufacturing and crafting, CNC (Computer Numerical Control) machines stand as beacons of innovation, transforming the way we realise our creative endeavours. These sophisticated gadgets are celebrated for their unparalleled accuracy, efficiency, and adaptability, becoming indispensable assets in a myriad of industries, from the fine art of woodworking to the rugged realm of metal fabrication.

If you find yourself in the UK, nurturing ambitions of elevating your projects to a new plane of excellence, you're exactly where you need to be. This detailed guide aims to navigate you through the vital aspects to ponder upon when on the quest to find the CNC machine that harmonises with your objectives and needs.

Stay with us as we unravel the intricacies of selecting a CNC machine that not only matches your requirements but also redefines what's possible in your craftsmanship journey. From intricate carvings to precision parts, your next masterpiece is just a CNC machine away!

Purpose and Project

Firstly, choosing the right CNC machine is understanding your specific needs and project scope. Are you a hobbyist working on intricate designs, or are you a professional looking to streamline production? Different machines excel at different tasks, so it's essential to define your purpose before proceeding.

Router, Milling, or Lathe

CNC machines come in various types, each tailored to specific applications. CNC routers are excellent for cutting, carving, and engraving in materials like wood and plastic. CNC milling machines are designed for precision metalworking and more complex tasks. CNC lathes, on the other hand, specialise in cylindrical workpieces. Identify which machine type aligns with your projects for optimal results.

Purpose and Project

Firstly, choosing the right CNC machine is understanding your specific needs and project scope. Are you a hobbyist working on intricate designs, or are you a professional looking to streamline production? Different machines excel at different tasks, so it's essential to define your purpose before proceeding.

Router, Milling, or Lathe

CNC machines come in various types, each tailored to specific applications. CNC routers are excellent for cutting, carving, and engraving in materials like wood and plastic. CNC milling machines are designed for precision metalworking and more complex tasks. CNC lathes, on the other hand, specialise in cylindrical workpieces. Identify which machine type aligns with your projects for optimal results.

Purpose and Project

Firstly, choosing the right CNC machine is understanding your specific needs and project scope. Are you a hobbyist working on intricate designs, or are you a professional looking to streamline production? Different machines excel at different tasks, so it's essential to define your purpose before proceeding.

Router, Milling, or Lathe

CNC machines come in various types, each tailored to specific applications. CNC routers are excellent for cutting, carving, and engraving in materials like wood and plastic. CNC milling machines are designed for precision metalworking and more complex tasks. CNC lathes, on the other hand, specialise in cylindrical workpieces. Identify which machine type aligns with your projects for optimal results.

Workspace and Size Constraints

The available workspace in your workshop is a significant role in determining the size of the CNC machine you can accommodate. Measure the available space and consider not only the machine's dimensions but also its required clearance for safe operation. This step ensures that the chosen CNC machine fits seamlessly into your workspace without causing logistical challenges.

Workspace and Size Constraints

The available workspace in your workshop is a significant role in determining the size of the CNC machine you can accommodate. Measure the available space and consider not only the machine's dimensions but also its required clearance for safe operation. This step ensures that the chosen CNC machine fits seamlessly into your workspace without causing logistical challenges.

Workspace and Size Constraints

The available workspace in your workshop is a significant role in determining the size of the CNC machine you can accommodate. Measure the available space and consider not only the machine's dimensions but also its required clearance for safe operation. This step ensures that the chosen CNC machine fits seamlessly into your workspace without causing logistical challenges.

Budget Considerations

CNC machines come in a wide price range, from entry-level models to high-end industrial machines. Setting an affordbale budget based on your requirements and project goals. Keep in mind that while cost is a factor, investing in a quality CNC machine can yield greater efficiency, accuracy, and longevity, making it a worthwhile long-term investment.

Budget Considerations

CNC machines come in a wide price range, from entry-level models to high-end industrial machines. Setting an affordbale budget based on your requirements and project goals. Keep in mind that while cost is a factor, investing in a quality CNC machine can yield greater efficiency, accuracy, and longevity, making it a worthwhile long-term investment.

Budget Considerations

CNC machines come in a wide price range, from entry-level models to high-end industrial machines. Setting an affordbale budget based on your requirements and project goals. Keep in mind that while cost is a factor, investing in a quality CNC machine can yield greater efficiency, accuracy, and longevity, making it a worthwhile long-term investment.

Software Suitability

The software used to operate the CNC machine is just as crucial as the hardware itself. Ensure that the machine you choose is compatible with industry-standard software, allowing you to create, import, and modify your designs seamlessly. Familiarise yourself with the software's learning curve and capabilities to determine if it suits your skill level and project requirements. We supply VCarve Pro or Fusion 360, with full training with all of our CNC machines.

Software Suitability

The software used to operate the CNC machine is just as crucial as the hardware itself. Ensure that the machine you choose is compatible with industry-standard software, allowing you to create, import, and modify your designs seamlessly. Familiarise yourself with the software's learning curve and capabilities to determine if it suits your skill level and project requirements. We supply VCarve Pro or Fusion 360, with full training with all of our CNC machines.

Software Suitability

The software used to operate the CNC machine is just as crucial as the hardware itself. Ensure that the machine you choose is compatible with industry-standard software, allowing you to create, import, and modify your designs seamlessly. Familiarise yourself with the software's learning curve and capabilities to determine if it suits your skill level and project requirements. We supply VCarve Pro or Fusion 360, with full training with all of our CNC machines.

Precision/Accuracy

One of the primary advantages of CNC machines is their precision. Pay close attention to the machine's accuracy specifications, including its tolerance levels and repeatability. Higher precision ensures that your projects are executed flawlessly, minimising errors and rework.

Aftercare Support

When choosing a CNC machine, consider the availability of customer support, technical assistance, and replacement parts. Research the manufacturer's reputation for customer service and evaluate the ease of obtaining support in case you encounter issues or require maintenance.

Before finalising your decision, read user reviews and seek recommendations from fellow creators or professionals in your industry. Real-world experiences can provide insights into a CNC machine's performance, durability, and overall satisfaction level.

Conclusion

Selecting the best CNC machine in the UK involves a careful balance of assessing your needs, understanding your projects, and considering the available options. By defining your purpose, considering machine types, evaluating workspace constraints, setting a budget, assessing software compatibility, prioritising precision, and seeking user feedback, you'll be well-equipped to make an informed decision that aligns with your creative ambitions. Embrace the power of CNC technology and elevate your craftsmanship to new heights.

Precision/Accuracy

One of the primary advantages of CNC machines is their precision. Pay close attention to the machine's accuracy specifications, including its tolerance levels and repeatability. Higher precision ensures that your projects are executed flawlessly, minimising errors and rework.

Aftercare Support

When choosing a CNC machine, consider the availability of customer support, technical assistance, and replacement parts. Research the manufacturer's reputation for customer service and evaluate the ease of obtaining support in case you encounter issues or require maintenance.

Precision/Accuracy

One of the primary advantages of CNC machines is their precision. Pay close attention to the machine's accuracy specifications, including its tolerance levels and repeatability. Higher precision ensures that your projects are executed flawlessly, minimising errors and rework.

Aftercare Support

When choosing a CNC machine, consider the availability of customer support, technical assistance, and replacement parts. Research the manufacturer's reputation for customer service and evaluate the ease of obtaining support in case you encounter issues or require maintenance.

Before finalising your decision, read user reviews and seek recommendations from fellow creators or professionals in your industry. Real-world experiences can provide insights into a CNC machine's performance, durability, and overall satisfaction level.

Conclusion

Selecting the best CNC machine in the UK involves a careful balance of assessing your needs, understanding your projects, and considering the available options. By defining your purpose, considering machine types, evaluating workspace constraints, setting a budget, assessing software compatibility, prioritising precision, and seeking user feedback, you'll be well-equipped to make an informed decision that aligns with your creative ambitions. Embrace the power of CNC technology and elevate your craftsmanship to new heights.

Before finalising your decision, read user reviews and seek recommendations from fellow creators or professionals in your industry. Real-world experiences can provide insights into a CNC machine's performance, durability, and overall satisfaction level.

Conclusion

Selecting the best CNC machine in the UK involves a careful balance of assessing your needs, understanding your projects, and considering the available options. By defining your purpose, considering machine types, evaluating workspace constraints, setting a budget, assessing software compatibility, prioritising precision, and seeking user feedback, you'll be well-equipped to make an informed decision that aligns with your creative ambitions. Embrace the power of CNC technology and elevate your craftsmanship to new heights.