- 0800 056 0404

- 0191 386 5303

- sales@opuscnc.co.uk

- Units 22A-D Roeburn House, Mandale Business Park, Durham. DH1 1TH

THE HOME OF

CNC ROUTERS

Industrial CNC Routers for all applications!

We are committed to providing cutting-edge CNC solutions that elevate your manufacturing resources to the next level. With a comprehensive range of high-performance CNC machines, including 3 axis, 4 axis, and 5 axis routers, we cater to businesses of all sizes and industries.

THE HOME OF

CNC ROUTERS

Industrial CNC Routers for all applications!

We are committed to providing cutting-edge CNC solutions that elevate your manufacturing resources to the next level. With a comprehensive range of high-performance CNC machines, including 3 axis, 4 axis, and 5 axis routers, we cater to businesses of all sizes and industries.

3 AXIS CNC ROUTER MODELS

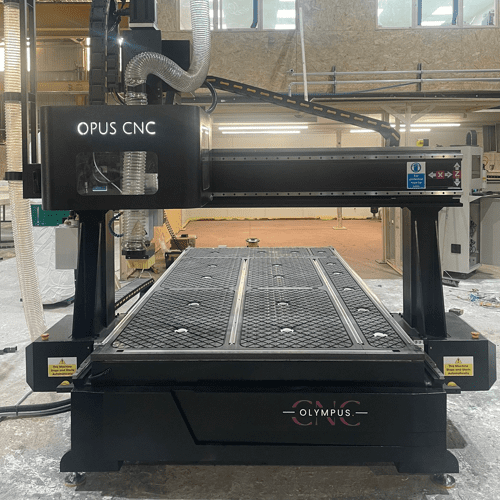

OLYMPUS

MANUAL TOOL CHANGE

The Olympus CNC router is an easy-to-use, industrial CNC machine with a 6kW air-cooled spindle and has a manual tool change.

The user-friendly Olympus CNC router can handle the most challenging jobs 24/7. It is a heavy-duty industrial CNC machine weighing over 2 tons.

This CNC machine is our most affordable CNC, yet remains a reliable and precise industrial CNC router. It is also ideal for those with no previous experience of CNC routing.

OLYMPUS PRO

MANUAL TOOL CHANGE

The Olympus PRO CNC router is a step up from the Olympus model and comes equipped with a 9kW HQD quick-release spindle, Opus PRO control system and servo motors & drives.

Importantly, in the future, it can be retrofitted with the 8 position linear rack, auto tool change system, making this CNC machine future-proof when needs change.

The Olympus PRO is an ideal CNC machine for those who require an adaptable CNC router, without breaking the bank!

OLYMPUS ATC

AUTOMATIC TOOL CHANGE

Are you looking for an affordable CNC router with an auto tool change? Then look no further than the Olympus ATC CNC router for up to 8 tools.

Olympus ATC routers come with the same spec as their sister model, the Olympus PRO. However, they already have the automatic tool change configured and ready to use.

The Olympus ATC is ideal for those need an automatic tool change machine, that is heavy-duty and with precision and accuracy.

PEGASUS ATC

AUTOMATIC TOOL CHANGE

The Pegasus ATC CNC router is a top-of-the-range CNC router with extensive features and consists of worldwide components found only on industry-leading CNC machines, without the price tag.

All Pegasus ATC CNC routers include a super-fast carousel automatic tool change for up to 12 tools, Yaskawa servo drives and motors, plus an Italian 9kW HSD spindle.

If you are in the market for a superior CNC router then look no further!

OLYMPUS

MANUAL TOOL CHANGE

The Olympus CNC is an easy-to-use, industrial CNC machine with a 6kW air-cooled spindle and has a manual tool change.

The user-friendly Olympus CNC router can handle the most challenging jobs 24/7. It is a heavy-duty industrial CNC machine weighing over 2 tons.

This CNC machine is our most affordable CNC, yet remains a reliable and precise industrial CNC router. It is also ideal for those with no previous experience of CNC routing.

OLYMPUS PRO

MANUAL TOOL CHANGE

The Olympus PRO CNC router is a step up from the Olympus model, but comes equipped with a 9kW HQD quick-release spindle, Opus PRO control system and servo motors & drives.

Importantly, in the future it can be retrofitted with the 8 position linear rack, auto tool change system, making this CNC machine future-proof when needs change.

The Olympus PRO is ideal for those who require an adaptable CNC, without breaking the bank!

OLYMPUS ATC

AUTOMATIC TOOL CHANGE

Are you looking for an affordable CNC router with an auto tool change? Then look no further than the Olympus ATC CNC router for up to 8 tools.

Olympus ATC routers come with the same spec as their sister model, the Olympus PRO. However, they already have the automatic tool change configured and ready to use.

The Olympus ATC is ideal for those need an automatic tool change machine, with precision and accuracy.

PEGASUS ATC

AUTOMATIC TOOL CHANGE

The Pegasus ATC CNC router is a top-of-the-range CNC machine with extensive features and consists of worldwide components found only on industry-leading CNC machines, without the price tag.

All Pegasus ATC CNC routers include a super-fast carousel automatic tool change for up to 12 tools, Yaskawa servo drives and motors, plus an Italian 9kW HSD spindle.

If you are in the market for a superior CNC router then look no further!

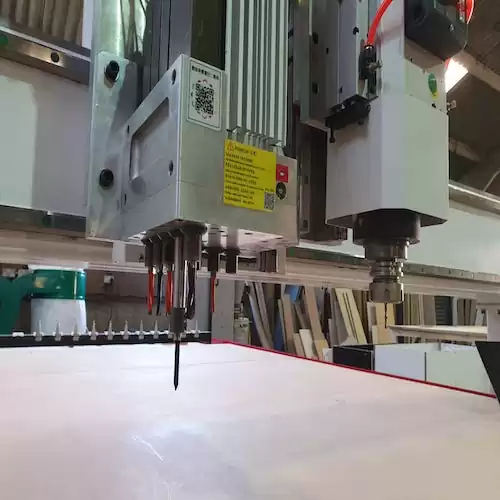

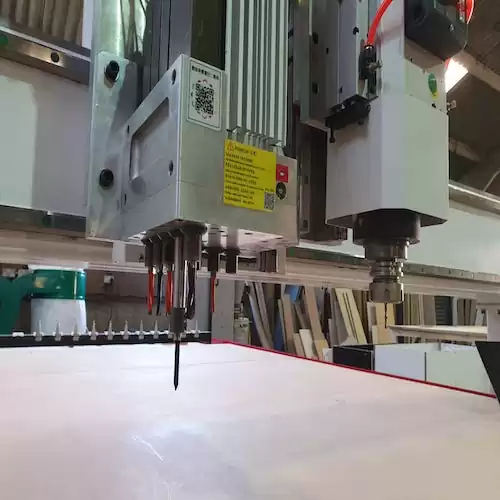

INTRODUCING....

THE MATRIX SIDE-DRILLING

CNC MACHINE

The Matrix Side-Drilling CNC Machine is designed for precision edge drilling and horizontal boring, ideal for cabinetry and panel furniture production. With user-friendly operation and high-speed performance, it ensures perfect alignment every time. A must-have addition for any workshop focused on efficiency and accuracy.

INTRODUCING.....

THE MATRIX SIDE-DRILLING

CNC MACHINE

The Matrix Side-Drilling CNC Machine is designed for precision edge drilling and horizontal boring, ideal for cabinetry and panel furniture production. With user-friendly operation and high-speed performance, it ensures perfect alignment every time. A must-have addition for any workshop focused on efficiency and accuracy.

4 & 5 AXIS CNC ROUTER MODELS

TETRA

4 AXIS CNC ROUTER

The new Tetra ATC CNC routers are available with a 4th axis. The 4th axis is available either as angular or rotational.

The rotational axis allows cylindrical works to be carried out. Angular allows side-drilling and shaping up to ± 90°. Also, the angular 4th axis offers side drilling and routing on 2 edges of material, which is ideal for kitchen cabinetry, plastic fabrication and door manufacturing.

Want to learn more about our new Tetra 4-axis CNC routers and all the features?

LOTUS

5 AXIS CNC ROUTER

The new Lotus 5-axis CNC router is known for its power and precision. With the combination of Fusion 360 and the Lotus 5-axis CNC router, you can take your creativity to the next level.

A standard CNC router functions on an X, Y & Z axis, limiting you to 2D creations, the Lotus 5-axis CNC router goes beyond that by utilising additional A & C axes.

Want to learn more about the impressive features and capabilities of this outstanding 5-axis CNC machine?

CNC Add-Ons

Not everyone requires an off-the-shelf CNC router. For that reason, all Opus CNC routers can be fitted with one of the below attachments.

It’s important to note that our CNC routers fitted with the attachments below are not stock machines and are manufactured from the point of order. If you are looking for a specialised CNC router, please speak to one of our CNC router experts for professional advice.

Oscillating Blade

A robust cutting tool intended for heavier, thicker and harder materials than a traditional knife can accommodate. Full directional control of the blade allows straight edges and sharp corners to be cut cleanly and accurately.

Tangential Knife

The tangential knife is suitable for softer materials such as leather, rubber and single-ply cloths which tend to fray easily, and require cuts to be cut with clean edges.

Creasing Wheel

The creasing wheel attachment precisely creases materials like cardboard, making it ideal for packaging folds. It is highly favoured in packaging manufacturing as it eliminates human error and delivers cleaner, more consistent results.

PC Controller

Boost your Opus CNC router’s performance with our networkable PC controller. Enjoy an intuitive interface, advanced toolpath editing, and seamless file management for greater efficiency and precision.

Compatible with all our routers, this upgrade includes expert installation and training.

Oscillating Blade

A robust cutting tool intended for heavier, thicker and harder materials than a traditional knife can accommodate. Full directional control of the blade allows straight edges and sharp corners to be cut cleanly and accurately.

Tangential Knife

The tangential knife is suitable for softer materials such as leather, rubber and single-ply cloths which tend to fray easily, and require cuts to be cut with clean edges.

Creasing Wheel

The creasing wheel attachment precisely creases materials like cardboard, making it ideal for packaging folds. It is highly favoured in packaging manufacturing as it eliminates human error and delivers cleaner, more consistent results.

PC Controller

Boost your Opus CNC router’s performance with our networkable PC controller. Enjoy an intuitive interface, advanced toolpath editing, and seamless file management for greater efficiency and precision.

Compatible with all our routers, this upgrade includes expert installation and training.

Rotary Device

Enables full 360° rotation of the workpiece for the perfect cylindrical carving and engraving, making it possible to machine profile bars and posts, such as newels for staircases and table or chair legs, with speed and ease.

Drill Bank

The drill head has the capacity to hold up to 9 drill bits for a wide range of machining. It is suitable for a vast range of materials including non-ferrous metals, plastics, woods and composite materials.

CCD Camera

The CCD camera detects pre-printed registration marks to determine the exact cutting toolpath. This is mainly used in conjunction with large-format printers and is ideal for sign-makers.

Gantry Height

Designed for machining thicker or bulkier materials, a high gantry clearance allows for greater flexibility in accommodating workpieces with substantial height. This feature is particularly beneficial for industries working with foam, timber blocks, or stacked materials, ensuring precision and efficiency without compromising on material size.

Rotary Device

Enables full 360° rotation of the workpiece for the perfect cylindrical carving and engraving, making it possible to machine profile bars and posts, such as newels for staircases and table or chair legs, with speed and ease.

Drill Bank

The drill head has the capacity to hold up to 9 drill bits for a wide range of machining. It is suitable for a vast range of materials including non-ferrous metals, plastics, woods and composite materials.

CCD Camera

The CCD camera detects pre-printed registration marks to determine the exact cutting toolpath. This is mainly used in conjunction with large-format printers and is ideal for sign-makers.

Gantry Height

Designed for machining thicker or bulkier materials, a high gantry clearance allows for greater flexibility in accommodating workpieces with substantial height. This feature is particularly beneficial for industries working with foam, timber blocks, or stacked materials, ensuring precision and efficiency without compromising on material size.

Automatic Tables Loading & Offloading

We all know how tricky it can be loading large sheets of material onto a CNC machine manually. Therefore, all Opus CNC routers can be manufactured to accommodate the automatic loading and offloading tables; making material placing a whole lot easier!

Just ask one of our engineers for more information.

Automatic Tables

Loading & Offloading

We all know how tricky it can be loading large sheets of material onto a CNC machine manually. Therefore, all Opus CNC routers can be manufactured to accommodate the automatic loading and offloading tables; making material placing a whole lot easier!

Just ask one of our engineers for more information.

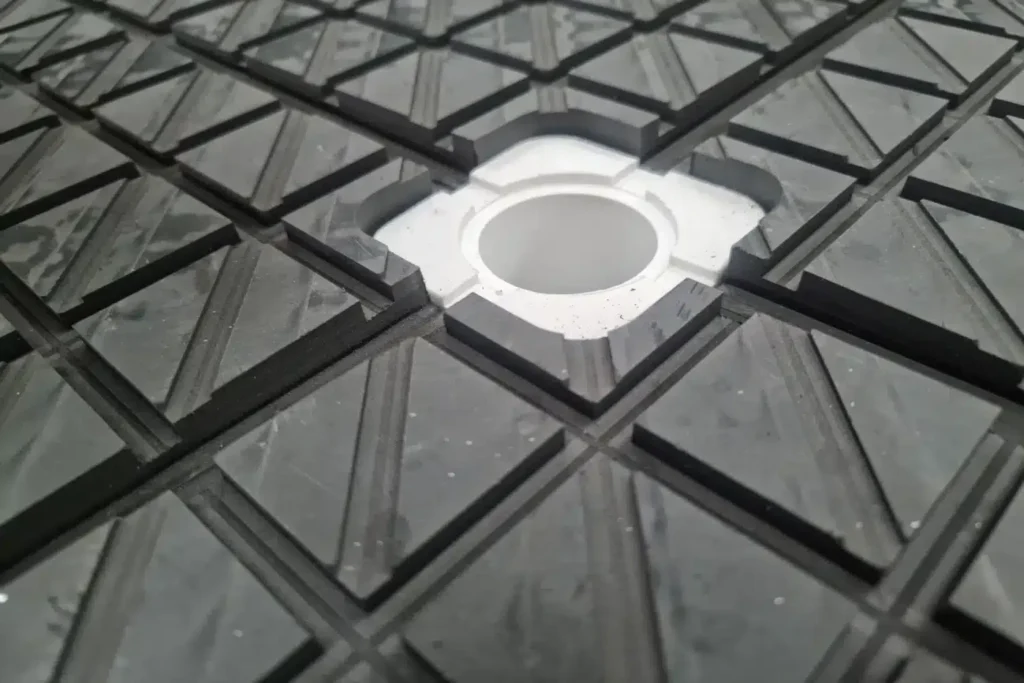

What makes our vacuum beds stand out?

The Opus team of engineers have designed all Opus CNC routers to offer superior suction, throughout all of our CNC machines!

Extreme Suction

A common concern with standard CNC routers is the loss of suction at the edges of the vacuum bed. Why? Most CNC router machines have a standard bed layout with uniform shallow channels. These superficial channels restrict the airflow as it moves away from each vacuum hole, giving a significant loss of suction.

We have designed all vacuum beds on an Opus CNC router to come equipped with a tapered vacuum matrix bed with much deeper grooves radiating away from each vacuum hole. This tapered grid bed allows maximum airflow throughout without restriction, even to the extremities of each bed zone.

Practical Zoning

We have redesigned the vacuum bed zones to provide maximum suction for various material sizes. Our CNC routers with bed sizes of at least 10′ x 5′ deliver optimal suction when working with both 8′ x 4′ and 10′ x 5′ sheets.

The grid below illustrates how a 10′ x 5′ CNC router is zoned to accommodate both 10′ x 5′ and 8′ x 4′ sheets, ensuring maximum suction for these specific sizes as well as full coverage across the entire bed.

Do I need an

Automatic Tool Change ?

Efficiency and Productivity: The auto tool change (ATC) allows a CNC machine to change tools automatically without manual intervention. This reduces downtime between machining operations, leading to increased efficiency and productivity. Operators can load multiple tools into the ATC rack, and the machine can select and change tools as needed, enabling uninterrupted machining.

Reduced Human Error: Manual tool changes are susceptible to human error, such as selecting or misaligning the wrong tool. An ATC eliminates these errors by precisely selecting and positioning the correct tool according to the CNC program.

Consistency and Accuracy: An ATC ensures that the same tool is used consistently throughout a machining process, leading to greater accuracy and consistent results. This is particularly important in industries where precision is critical, such as aerospace or medical device manufacturing.

Unattended Operation: An ATC-equipped CNC machine can run unattended for extended periods. Once programmed, the machine can automatically change tools and continue the machining process, allowing operators to focus on other tasks or run multiple machines simultaneously.

Reduced Setup Time: A manual tool change can be time-consuming when a machine needs different tools for various operations. With an ATC, setup time is significantly reduced, as the machine can swap out tools with minimal delay.

Do I need an

Automatic Tool Change?

Efficiency and Productivity: The auto tool change allows a CNC machine to change tools automatically without manual intervention. This reduces downtime between machining operations, leading to increased efficiency and productivity. Operators can load multiple tools into the ATC magazine, and the machine can select and change tools as needed, enabling uninterrupted machining.

Reduced Human Error: Manual tool changes are susceptible to human error, such as selecting or misaligning the wrong tool. An ATC eliminates these errors by precisely selecting and positioning the correct tool according to the CNC program.

Consistency and Accuracy: An ATC ensures that the same tool is used consistently throughout a machining process, leading to greater accuracy and consistent results. This is particularly important in industries where precision is critical, such as aerospace or medical device manufacturing.

Unattended Operation: An ATC-equipped CNC machine can run unattended for extended periods. Once programmed, the machine can automatically change tools and continue the machining process, allowing operators to focus on other tasks or run multiple machines simultaneously.

Reduced Setup Time: A manual tool change can be time-consuming when a machine needs different tools for various operations. With an ATC, setup time is significantly reduced, as the machine can swap out tools with minimal delay.

What software is included?

We supply VCarve Pro with all our 3-axis CNC router machines as standard. VCarve Pro offers a user-friendly platform with a range of features that cater to CNC routing, engraving, and carving needs.

Its focus on ease of use, design flexibility, and toolpath generation makes it a popular choice for those looking to create intricate and decorative designs using CNC technology. VCarve Pro is ideal for our 3-axis CNC routers.

As our engineers are trained in Autodesk Fusion 360, a comprehensive 3D CAD, CAM, and CAE software, this offers numerous benefits across a variety of industries and applications. Fusion 360 is an ideal choice for our 4 and 5 axis CNC routers.

What is included with

an Opus CNC router?

Delivery

All 1313, 1325 and 1530 models are delivered by a curtainsider lorry. Therefore, a forklift is required to offload.

2030, 2040 and 2060 models are delivered by a HIAB, so no forklift is required to offload.

Installation

All of our CNC routers include installation by one of our experienced engineers. We will carry out the full installation, including the wiring in of the extraction unit. It normally takes approximately one day for the installation of an Opus CNC router.

Training

We carry out full machine and software training. We also give clear instructions on housekeeping. The engineer will tailor the training around your capabilities and needs, in a friendly and patient manner.

CNC MODELS

Olympus

CNC Router

Tool Change Type: Manual Tool Change

Spindle: 6kW HQD Air-cooled Spindle

Drives: Stepper Drives

Motors: Stepper Motors

Control System: DSP Hand Controller

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 3.0kW Extraction System Included

Software Included: VCarve Pro

Delivery: Included

Installation: Included

Training: Machine and Software Training Included

Upgrades Available: PC Control System

Prices from £10,995 plus VAT

Olympus PRO

CNC Router

Tool Change Type: Manual Tool Change – Can be upgraded to ATC

Spindle: 9kW HQD Air-cooled Quick-release Spindle

Drives: Delta Servo Drives

Motors: Delta Servo Motors

Control System: Opus PRO Hand Controller

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 5.5kW Extraction System Included

Software Included: VCarve Pro

Delivery: Included

Installation: Included

Training: Machine and Software Training Included

Upgrades Available: PC Control System

Prices from £15,495 plus VAT

Olympus ATC

CNC Router

Tool Change Type: Linear 8 x ISO 30 Automatic Tool Change

Spindle: 9kW HQD Air-cooled Quick-release Spindle

Drives: Delta Servo Drives

Motors: Delta Servo Motors

Control System: Opus PRO Hand Controller

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 5.5kW Extraction System Included

Software Included: VCarve Pro

Delivery: Included

Installation: Included

Training: Machine and Software Training Included

Upgrades Available: PC Control System

Prices from £16,995 plus VAT

Pegasus ATC

CNC Router

Tool Change Type: Carousel 12 x ISO 30 Tools/Automatic Tool Change

Spindle: 9kW Italian HSD Spindle

Drives: Yaskawa Servo Drives

Motors: Yaskawa Servo Motors

Control: Syntec Control System

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 7.5kW Extraction System Included

Extras: Material Locating Pins | Bearing Wipers

Software Included: VCarve Pro

Delivery: Included

Installation: Included

Training: Machine and Software Training Included

Prices from £25,000 plus VAT

Tetra 4 Axis

CNC Router

Tool Change Type: Carousel 12 x ISO 30 Tools/Automatic Tool Change

Spindle: 9kW Italian HSD Spindle

Drives: Yaskawa Servo Drives

Motors: Yaskawa Servo Motors

Control: Syntec Control System

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 7.5kW Extraction System Included

Extras: Material Locating Pins | Bearing Wipers

4 Axis: Choice of Rotary or Angular

Software Included: VCarve Pro

Delivery: Included

Installation: Included

Prices TBC

Lotus 5 Axis

CNC Router

Tool Change Type: Carousel 12 x HSK-63 Tools/Automatic Tool Change

Spindle: 12kW Hiteco 5 Axis Spindle Options

Drives: Yaskawa Servo Drives

Motors: Yaskawa Servo Motors

Control: Syntec 5 Axis Control System

Bed: Vacuum Bed with Matrix Zones

Zones: Automatic On/Off Switches

Extraction: 7.5kW Extraction System Included

Extras: Material Locating Pins | Bearing Wipers

Software Included: Fusion 360

Delivery: Included

Installation: Included

Training: Machine and Software Training Included

Prices TBC

Trusted By