Comapre the Olympus ATC & the Pegasus ATC

See which CNC router is best for your production — side-by-side features, strengths, and recommended use-cases.

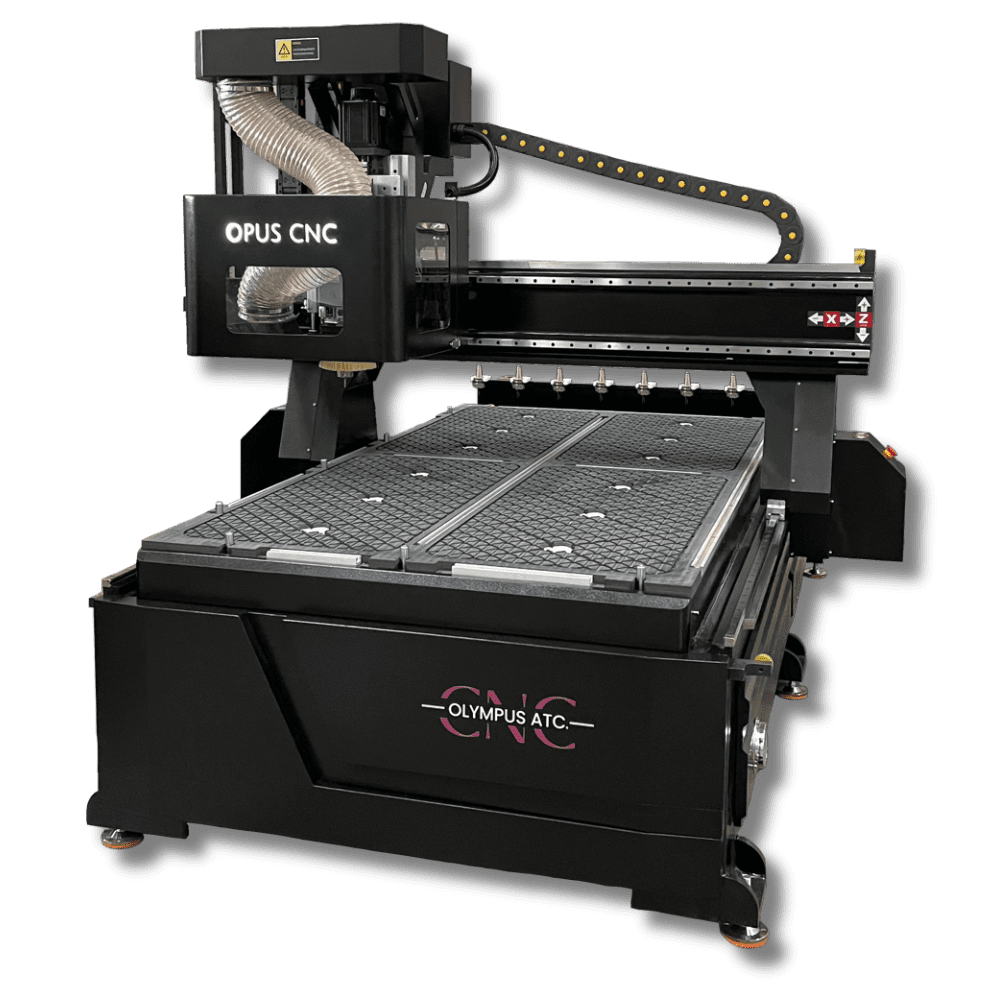

Olympus ATC

Pegasus ATC

Choose Olympus ATC if you need:

- Best-value ATC CNC router for workshops

- Heavy-duty build for daily production

- Reliable 8-tool linear rack system

- Single-phase power option available

- Flexible upgrade path for pumps and drives

Choose Pegasus ATC if you need:

- 12-tool carousel for super-fast tool changes

- Italian HSD ES951 9 kW spindle as standard

- Yaskawa servo motors & drives for precision

- Larger vacuum pumps and 7.5 kW extraction

- Built for continuous, high-duty production

Side‑by‑Side Comparison

| Area | Olympus ATC CNC router | Pegasus ATC CNC router |

|---|---|---|

| Best for | Value-led ATC production, joinery/signage, job shops | High-duty production, complex multi-tool jobs, faster cycle times |

| Tool-change system | Linear rack, up to 8 tools | Carousel, 12 tools |

| Spindle | 9kW HQD quick-release spindle | Italian HSD ES951 9kW |

| Drives | Delta servos & drives | Japanese Yaskawa servos & drives |

| Control | Opus PRO Controller | Taiwanese Syntec Control System |

| Vacuum bed | Upgraded matrix-zoned bed | Upgraded matrix-zoned bed |

| Vacuum pumps | 1-4 x 5.5kW dual-stage pumps | 1-4 x 7.5kW dual-stage pumps |

| Dust extraction | 5.5 kW options | 7.5 kW system |

| Common bed sizes | 1325, 1530, 2030 | 1325, 1530, 2030 |

| Power | Single-phase available on select models; 3-phase options | Single-phase available on select models; 3-phase options |

| Warranty | 24-month parts & labour | 24-month parts & labour |

| Software | VCarve Pro (lifetime licence) | VCarve Pro (lifetime licence) |

| Aftercare | Lifetime phone/email support + Customer Portal | Lifetime phone/email support + Customer Portal |

| Notes: Exact component/spec depends on size & configuration. Our team of engineers will confirm the optimal build for your workflow. | ||

Why Choose Olympus or Pegasus ATC?

Olympus ATC

The Olympus ATC brings you true automatic tool change at a lower entry cost. It’s a dependable choice for workshops that want durability and flexibility without overspending.

8-tool linear rack

A simple, reliable system that automates tool changes without the cost of a carousel.

Heavy-duty build quality

Proven across UK workshops, designed for long-term, high-use reliability.

Flexible upgrades

Add servos, extra vacuum, or stronger extraction as your production grows.

Matrix-zoned vacuum bed

Enhanced suction keeps materials stable for accurate cutting across the sheet.

Affordable entry point

Full ATC capability at a lower investment, ideal for cost-conscious businesses.

Pegasus ATC

If speed and efficiency are your priorities, the Pegasus ATC delivers. Premium components and faster tool changes make it ideal for workshops running multiple shifts and complex jobs.

12-tool carousel close to the spindle

Swaps tools in seconds with minimal travel, saving minutes per sheet and hours across a shift.

9kW Italian HSD ES951 spindle

A premium industrial spindle designed for continuous operation and demanding materials.

Yaskawa servos and drives

Smooth motion and high feed speeds deliver clean edges and precise results.

High-capacity vacuum pumps

Reliable hold-down even on porous boards, reducing the need for tabs or onion-skins.

7.5kW extraction system

Clears dust efficiently, keeping cut quality consistent and the workshop safer.

Typical Use-Cases

See how Olympus ATC and Pegasus ATC fit into real-world industries and applications.

Plastics Fabrication

High suction and stable motion are key for plastics. The Pegasus provides consistent results in high-volume runs, while the Olympus delivers dependable performance in mixed-material workshops.

Joinery & Cabinetry

Cut MDF, chipboard, and laminates with precision. The Olympus offers superb value for smaller shops, while the Pegasus speeds up production for multi-shift cabinet makers.

Signage & Display

Both routers excel at acrylics, foams, and composites. The Pegasus’ servo system handles complex multi-tool workflows faster, while the Olympus remains a cost-effective all-rounder.

Included as Standard

What You Get with Every Machine

24-Month Warranty

Full parts & labour cover on every machine.

Delivery & Installation

Handled by our own engineers nationwide.

Engineer-Led Training

Comprehensive setup and operator training included.

Matrix-Zoned Vacuum Bed

Enhanced hold-down for stable sheet cutting.

Material Locating Pins

Precision features built in for accurate results.

VCarve Pro Licence

Perpetual CAM software licence with every machine.

Lifetime Phone & Email Support

Direct access to Opus engineers whenever you need us.

Customer Portal Access

Exclusive online resources, updates, and guides.

Optional Upgrades

Customise your Olympus or Pegasus to meet specific production needs.

Upgrade to additional or stronger dual-stage pumps for maximum hold-down on larger or porous boards.

Boost efficiency with higher-capacity extraction systems, keeping your work area clean and cuts precise.

Router tooling bundles for cabinetry, signage, plastics, and aluminium, tailored to your applications.

Expand functionality for side-routing, lock cases, hinges, and angled cuts with aggregates and C-axis rotation.

Essential for machining aluminium and composites, reducing heat build-up and extending tool life.

Upgrade to full PC integration with advanced networking, remote monitoring, and workflow automation.

Still Unsure? Book an Engineer-Led Demo in Our Durham Showroom

See Both Machines in Action Before You Decide

Frequently Asked Questions

Answers to the questions we hear most about the Olympus ATC and Pegasus ATC.

Yes — both the Olympus ATC and Pegasus ATC can be configured for single-phase or 3-phase power, depending on your site setup.

Most joinery jobs run 4–8 tools. If you frequently use more than 8, or want the fastest possible swaps, the Pegasus with its 12-tool carousel is the better choice. If you require a machine with more tooling options, please give us a call to discuss.

Yes — both ranges support aggregates and optional C-axis configurations. Tell us your operations (lock cases, hinges, angled cuts) and we’ll recommend the right setup.

Every machine comes with a lifetime licence for VCarve Pro. Many customers also integrate with other CAD/CAM software — ask us for compatibility advice.

Lead times vary depending on machine size and configuration. Stock models are available more quickly, within days if needed, while custom builds may take 16–20 weeks.

Yes — we provide flexible finance and leasing solutions, through our Asset Finance partner – Anglo-Scottish to help spread the cost. Their team can outline options tailored to your business.

Every customer gets lifetime phone and email support, access to our online Customer Portal, and the reassurance of our in-house engineering team for ongoing service.

Need advice choosing? Call us on 0191 386 5303 or email sales@opuscnc.co.uk