The Hidden Costs of Owning a CNC Machine (and How to Avoid Them)

Practical advice from the team at Opus CNC — because knowing what really costs you time and money can save you both.

The Real Cost of CNC Ownership

Buying a CNC router or laser is one of the most significant investments a workshop will ever make. You do your research, compare specs, read reviews, and finally find the machine that feels right for you. But what many first-time owners don’t realise is that the purchase price is only part of the story.

Owning a CNC machine comes with ongoing costs — some expected, some not so obvious — that can make a real difference to your bottom line if you’re not prepared for them.

The good news? With a bit of planning and good habits, most of these costs can be reduced or even avoided altogether.

Tooling: The Cost That Never Stops

Every cut wears a tool down, and every material wears it away differently. The type of cutter you use, the force with which you push it, and the cleanliness of your material will all affect its lifespan.

We often see new owners surprised by how quickly tooling bills add up, especially in high-throughput workshops. It’s not unusual for companies to spend hundreds of pounds a month on replacement tools — particularly if they’re cutting a mix of materials like MDF, birch ply, or aluminium.

One of the most significant hidden costs is using the wrong type of tool for the job. A compression cutter may provide a cleaner edge on veneered boards, but using it on solid wood will wear it out twice as fast. Similarly, blunt or cheap cutters generate heat, causing burning or rough edges that waste material and time.

How to avoid unnecessary costs:

- Use the proper feeds, speeds, and pass depths to maximise tool life.

- Keep collets clean and replace them regularly — it’s a small cost that yields significant savings.

Tip: Invest in high-quality tooling — cheap cutters blunt faster and cost more in the long run.

Tooling: The Cost That Never Stops

Every cut wears a tool down, and every material wears it away differently. The type of cutter you use, the force with which you push it, and the cleanliness of your material will all affect its lifespan.

We often see new owners surprised by how quickly tooling bills add up, especially in high-throughput workshops. It’s not unusual for companies to spend hundreds of pounds a month on replacement tools — particularly if they’re cutting a mix of materials like MDF, birch ply, or aluminium.

One of the most significant hidden costs is using the wrong type of tool for the job. A compression cutter may provide a cleaner edge on veneered boards, but using it on solid wood will wear it out twice as fast. Similarly, blunt or cheap cutters generate heat, causing burning or rough edges that waste material and time.

How to avoid unnecessary costs:

- Use the proper feeds, speeds, and pass depths to maximise tool life.

- Keep collets clean and replace them regularly — it’s a small cost that yields significant savings.

Tip: Invest in high-quality tooling — cheap cutters blunt faster and cost more in the long run.

Extraction and Filtration

Extraction is one of those areas where people often try to save money up front, but poor extraction quickly becomes a headache. Blocked filters, damaged pumps, or dust build-up can lead to machine wear, overheating, or even health and safety issues.

Good extraction doesn’t just protect your equipment — it also protects your operators. Fine MDF dust, for instance, can cause respiratory irritation, and build-up inside your machine enclosure reduces airflow and clogs sensors. A few minutes of cleaning or filter replacement each week can save hours of downtime in the future.

We’ve seen customers who went from constant blockages to none at all after upgrading to a correctly matched extraction system. It’s a small investment that pays for itself many times over in reliability and air quality.

Regular maintenance makes the difference:

- Clean or replace filters as part of your weekly routine.

- Check ducting for leaks or blockages.

- Don’t cut corners on filtration — it protects your team and your investment.

Tip: A well-maintained extraction system will pay for itself in reliability and peace of mind.

Extraction and Filtration

Extraction is one of those areas where people often try to save money up front, but poor extraction quickly becomes a headache. Blocked filters, damaged pumps, or dust build-up can lead to machine wear, overheating, or even health and safety issues.

Good extraction doesn’t just protect your equipment — it also protects your operators. Fine MDF dust, for instance, can cause respiratory irritation, and build-up inside your machine enclosure reduces airflow and clogs sensors. A few minutes of cleaning or filter replacement each week can save hours of downtime in the future.

We’ve seen customers who went from constant blockages to none at all after upgrading to a correctly matched extraction system. It’s a small investment that pays for itself many times over in reliability and air quality.

Regular maintenance makes the difference:

- Clean or replace filters as part of your weekly routine.

- Check ducting for leaks or blockages.

- Don’t cut corners on filtration — it protects your team and your investment.

Tip: A well-maintained extraction system will pay for itself in reliability and peace of mind.

Downtime: The Most Expensive Cost of All

When your machine stops, so does your production. Whether it’s a worn bearing, a misaligned spindle, or a software glitch, unplanned downtime can cost far more than the part itself — it costs time, missed deadlines, and unhappy customers.

The best way to avoid it is through consistent preventative maintenance. Simple habits make all the difference: vacuum the bed each day, check oil and lubrication levels weekly, and tighten bolts before they have a chance to vibrate loose.

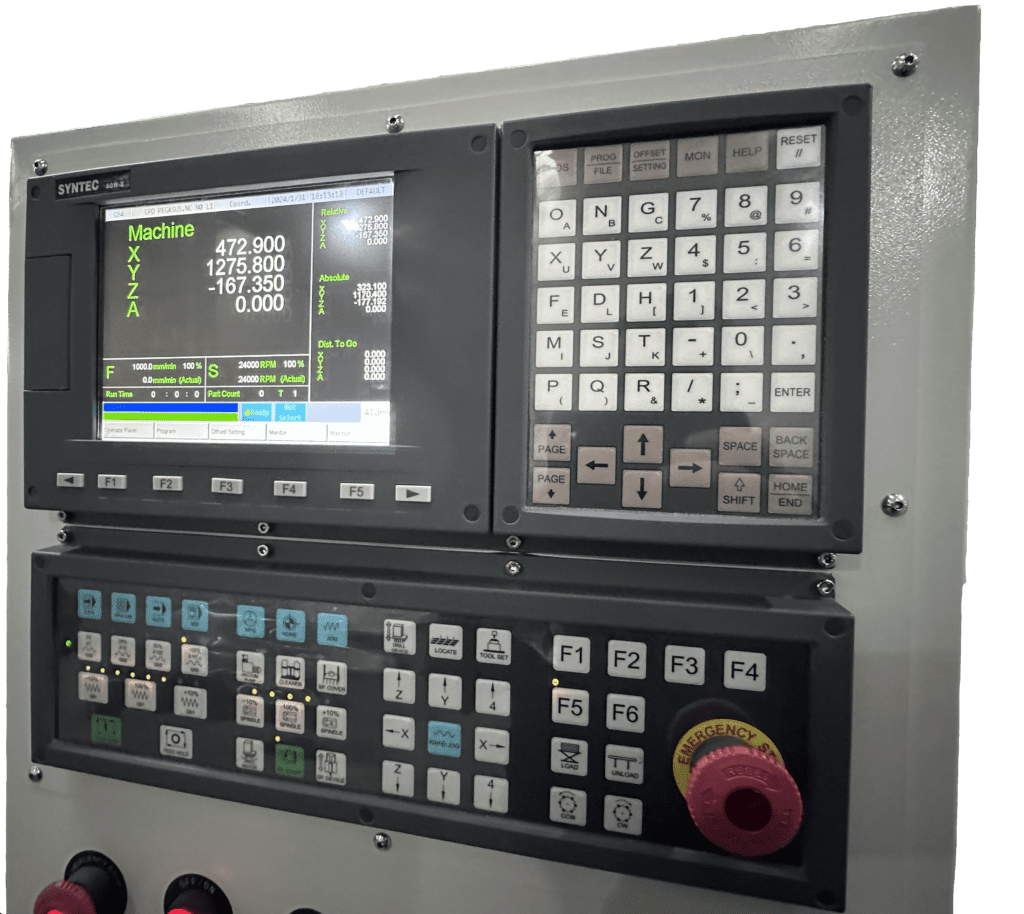

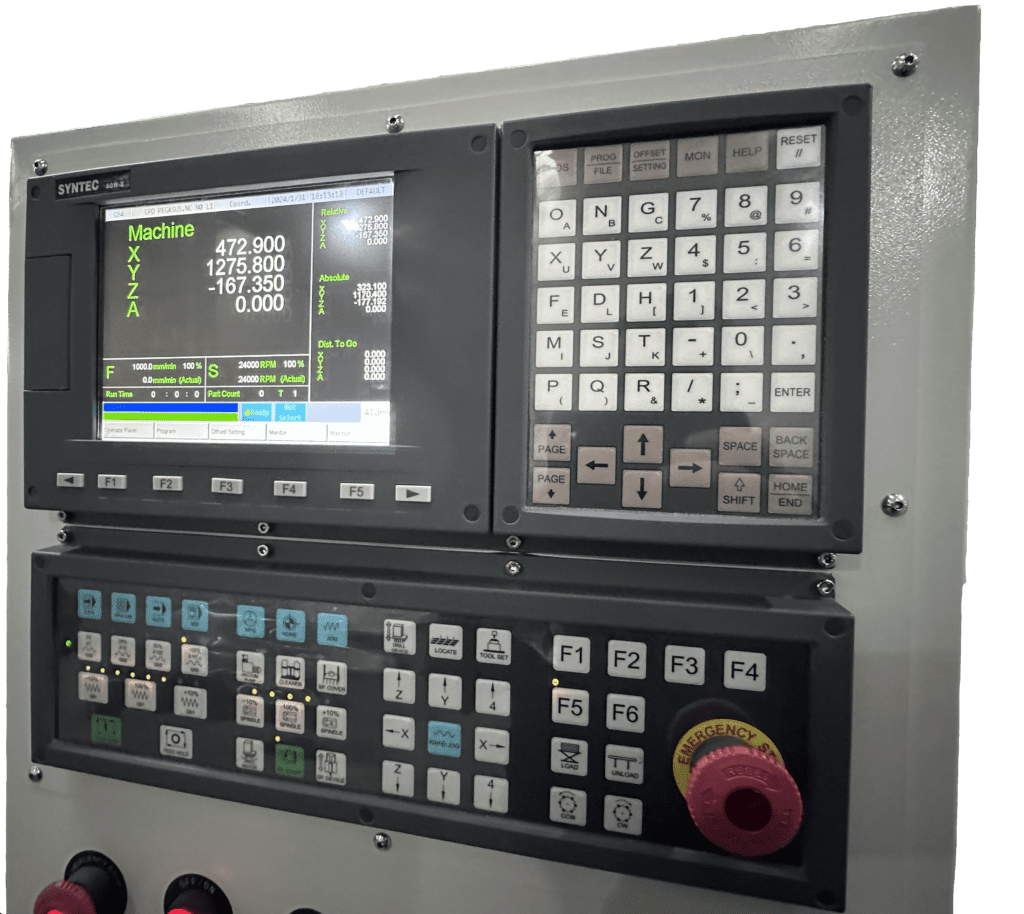

We recommend keeping a quick visual maintenance checklist next to your control panel — that alone can prevent most of the downtime we see in the field.

Routine maintenance to reduce downtime:

Clean and inspect the bed daily.

Check lubrication and air supply weekly.

Tighten bolts and connections monthly.

Schedule a professional service annually.

Tip: A few minutes of care each week is worth far more than a day of lost production.

Downtime: The Most Expensive Cost of All

When your machine stops, so does your production. Whether it’s a worn bearing, a misaligned spindle, or a software glitch, unplanned downtime can cost far more than the part itself — it costs time, missed deadlines, and unhappy customers.

The best way to avoid it is through consistent preventative maintenance. Simple habits make all the difference: vacuum the bed each day, check oil and lubrication levels weekly, and tighten bolts before they have a chance to vibrate loose.

We recommend keeping a quick visual maintenance checklist next to your control panel — that alone can prevent most of the downtime we see in the field.

Routine maintenance to reduce downtime:

- Clean and inspect the bed daily.

- Check lubrication and air supply weekly.

- Tighten bolts and connections monthly.

- Schedule a professional service annually.

Tip: A few minutes of care each week is worth far more than a day of lost production.

Software and File Preparation

Another hidden cost is time — particularly when it comes to file setup and software management. If your files aren’t optimised, your machine spends more time travelling between cuts than actually cutting. That extra movement increases wear on the motors and costs you electricity every single job.

A well-prepared toolpath can save hours each week. Proper nesting, efficient lead-ins and outs, and correct step-down settings all make a difference. It’s also worth revisiting your design software from time to time; new features often introduce more innovative ways to handle toolpaths and reduce runtime.

Practical tips:

- Utilise templates for recurring tasks to reduce setup time.

- Group similar materials or bit sizes together for fewer tool changes.

- Simulate before you cut — wasted material is one of the most expensive mistakes.

Tip: The more efficiently your software is set up, the more your CNC works for you, not the other way around.

Software and File Preparation

Another hidden cost is time — particularly when it comes to file setup and software management. If your files aren’t optimised, your machine spends more time travelling between cuts than actually cutting. That extra movement increases wear on the motors and costs you electricity every single job.

A well-prepared toolpath can save hours each week. Proper nesting, efficient lead-ins and outs, and correct step-down settings all make a difference. It’s also worth revisiting your design software from time to time; new features often introduce more innovative ways to handle toolpaths and reduce runtime.

Practical tips:

- Utilise templates for recurring tasks to reduce setup time.

- Group similar materials or bit sizes together for fewer tool changes.

- Simulate before you cut — wasted material is one of the most expensive mistakes.

Tip: The more efficiently your software is set up, the more your CNC works for you, not the other way around.

Electricity and Air Supply

Depending on your workshop setup, running costs can vary significantly. A 7.5kW extraction system and a pair of vacuum pumps running all day can add up, especially during longer jobs.

Being mindful of how you use your machine doesn’t mean cutting corners — it means planning smarter. Batch similar cuts together to minimise the time your vacuum and extraction run. Use energy monitors to see which parts of your setup draw the most power and whether your compressor or pumps are left running idle between jobs.

Simple ways to save energy:

- Turn off unused vacuum zones.

- Batch jobs to reduce idle time.

- Keep compressors properly serviced for better efficiency.

Tip: Even a 10% reduction in energy waste can make a noticeable difference over a year of daily production.

Electricity and Air Supply

Depending on your workshop setup, running costs can vary significantly. A 7.5kW extraction system and a pair of vacuum pumps running all day can add up, especially during longer jobs.

Being mindful of how you use your machine doesn’t mean cutting corners — it means planning smarter. Batch similar cuts together to minimise the time your vacuum and extraction run. Use energy monitors to see which parts of your setup draw the most power and whether your compressor or pumps are left running idle between jobs.

Simple ways to save energy:

- Turn off unused vacuum zones.

- Batch jobs to reduce idle time.

- Keep compressors properly serviced for better efficiency.

Tip: Even a 10% reduction in energy waste can make a noticeable difference over a year of daily production.

Training and Operator Skill

Even the best CNC router is only as good as the person operating it. One of the most overlooked costs in any workshop is inefficient operation — an untrained or uncertain operator can waste material, time, and tooling without realising it.

Training isn’t a one-off event at installation — it’s an ongoing process. As your projects evolve, so should your team’s understanding of software, cutting techniques, and maintenance. We regularly see workshops increase output simply because operators become more confident in adjusting speeds, feeds, and depths intelligently.

- Encourage your operators to ask questions, test new approaches, and share what they learn with the rest of the team. Minor improvements quickly compound into significant efficiency gains.

Tip: The more skilled the operator, the less strain on the machine — and the higher the quality of every job.

Training and Operator Skill

Even the best CNC router is only as good as the person operating it. One of the most overlooked costs in any workshop is inefficient operation — an untrained or uncertain operator can waste material, time, and tooling without realising it.

Training isn’t a one-off event at installation — it’s an ongoing process. As your projects evolve, so should your team’s understanding of software, cutting techniques, and maintenance. We regularly see workshops increase output simply because operators become more confident in adjusting speeds, feeds, and depths intelligently.

Encourage your operators to ask questions, test new approaches, and share what they learn with the rest of the team. Minor improvements quickly compound into significant efficiency gains.

Tip: The more skilled the operator, the less strain on the machine — and the higher the quality of every job.

Final Thoughts From the Workshop Floor

Owning a CNC machine isn’t just about having the right equipment — it’s about running it smartly. The best workshops we visit aren’t necessarily the ones with the biggest machines; they’re the ones where the team takes pride in keeping everything sharp, clean, and efficient.

Every cutter you save, every filter you clean, and every hour of downtime you prevent adds up. Over the course of a year, it can be the difference between merely owning a CNC and truly mastering it.