The Difference Between a CNC Router and a CNC Milling Machine

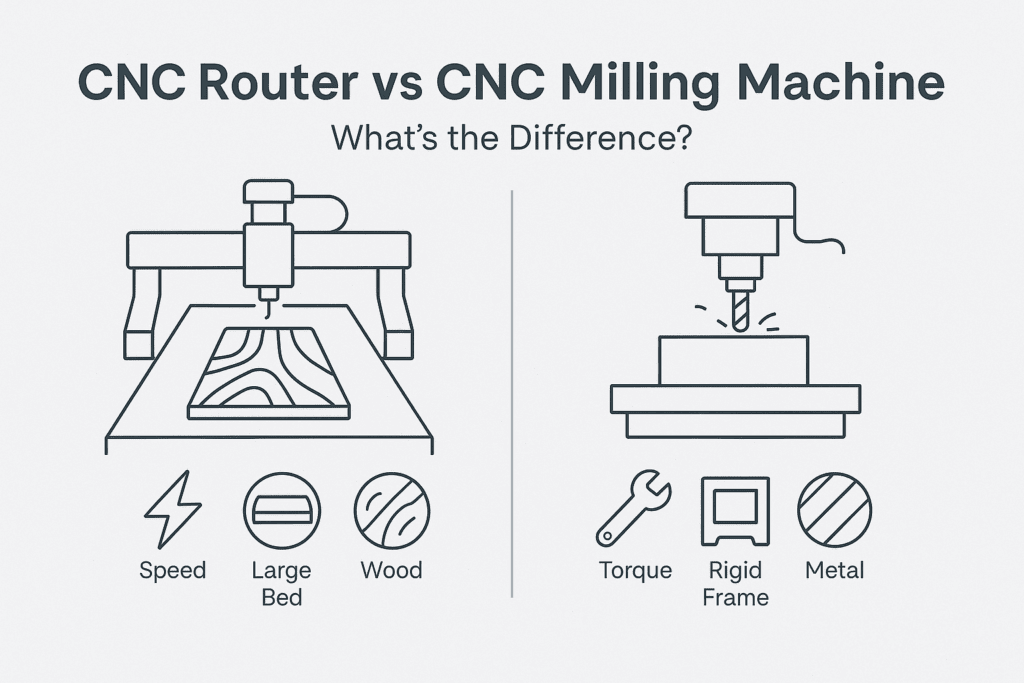

CNC routers and CNC milling machines share similar technology — both use computer-controlled cutting tools to shape materials with precision. However, they’re built for very different applications.

Understanding how they differ will help you choose the right machine for your workshop, materials, and production needs.

Applications at a Glance

| Machine Type | Ideal For | Typical Materials | Speed | Power |

|---|---|---|---|---|

| CNC Router | Joinery, signage, cabinetry, plastics, composites | Wood, MDF, acrylic, foam, aluminium | High-speed | Moderate torque |

| CNC Milling Machine | Engineering, metal fabrication, precision parts | Steel, brass, titanium, alloys | Slower speed | High torque |

Purpose and Typical Use

CNC Routers are primarily designed for cutting softer materials such as wood, MDF, plastic, foam, and non-ferrous metals like aluminium.

They excel in applications like joinery, furniture making, signage, and composite machining — where large sheet materials are common.

CNC Milling Machines, on the other hand, are built for heavier-duty tasks, machining metals such as steel, stainless steel, and titanium. They’re commonly found in engineering and precision component manufacturing.

Spindle Speed and Power

Routers use high-speed spindles — typically between 18,000 and 24,000 RPM — ideal for cutting and shaping wood and plastic quickly.

Milling machines operate at much lower spindle speeds, often between 1,000 and 10,000 RPM, but with far greater torque. This slower speed allows them to remove dense metal without damaging the tool.

💡 Example: The Olympus and Pegasus CNC routers from Opus CNC are fitted with Italian HSD or HQD spindles, offering high-speed precision cutting across a wide range of materials.

Frame and Build Design

A key difference lies in the machine structure.

CNC routers typically feature larger work areas and lighter gantries, optimised for cutting sheet materials up to 3 × 2 metres or more.

CNC milling machines are generally smaller but more rigid, built to handle the forces of machining solid metal blocks. Their frames are often made from cast iron or heavy steel for maximum stability.

Cutting Approach

Routers move the tool rapidly across a stationary workpiece, removing material in layers. This makes them ideal for 2D and 3D contouring, engraving, and full-depth cutting through sheets.

Milling machines use slower, deeper passes with greater precision in Z-axis depth, ideal for pocketing, drilling, and shaping metal components.

Control Systems and Tooling

Both machines rely on CNC control systems to automate motion, but routers usually feature more user-friendly interfaces and quick tool-change options.

For instance, Opus CNC’s Pegasus ATC routers include 12-position tool carousels, speeding up workflow across multi-tool projects. Milling machines often rely on complex toolholders and slower manual changes.

Ease of Use and Software Integration

CNC routers are generally easier to operate, with intuitive controls and quick setup for everyday production.

They integrate seamlessly with design software such as VCarve Pro and Fusion 360, ideal for workshops handling varied materials.

Milling machines typically require more advanced programming knowledge and setup time, making them better suited to specialist machining environments.

Which Machine Should You Choose?

If you’re working primarily with wood, MDF, composites, or plastics, a CNC router is your best choice — faster, easier to operate, and more versatile for sheet-based materials.

If your work involves solid metal machining or fine tolerances in mechanical parts, a CNC milling machine will provide the rigidity and precision required.

For most manufacturers, joiners, and fabricators, a high-quality industrial CNC router like the Olympus or Pegasus ATC offers the perfect balance of speed, precision, and value.