Why After-Sales Support Matters Just As Much As The Machine

When businesses invest in a CNC router or laser cutter, the focus is often on the machine itself, bed size, spindle power, servo drives, or laser wattage. While these technical specifications are important, the real long-term value comes from something often overlooked: after-sales support.

At Opus CNC, we regularly hear from businesses who bought machines elsewhere, only to find themselves let down when problems arise. Many of our current customers first came to us not for a new machine, but for help and advice when their original supplier failed to provide support.

Good after-sales service should also help you get more from your machine.

Our goal isn’t just to sell you a CNC or laser machine, it’s to be your long-term partner in production.

Optimising production workflows – advice on speeds, feeds, and cutting strategies to save time and reduce waste.

Tooling recommendations – helping you choose the right cutters and settings for wood, plastics, composites, or metals.

Software support – from VCarve Pro tips to troubleshooting toolpaths, ensuring smoother production runs.

Housekeeping and preventative maintenance – guidance on cleaning, lubrication, and checks that keep machines running reliably.

Annual service packages – full inspections and tune-ups to extend machine life and avoid costly downtime.

Training refreshers – for new staff members or to expand your team’s knowledge as your business grows.

Remote diagnostics – many issues can be spotted and fixed before they turn into real problems.

Upgrade and expansion advice – helping you plan for the future, whether that’s adding an automatic tool changer, oscillating knife, or even a second machine.

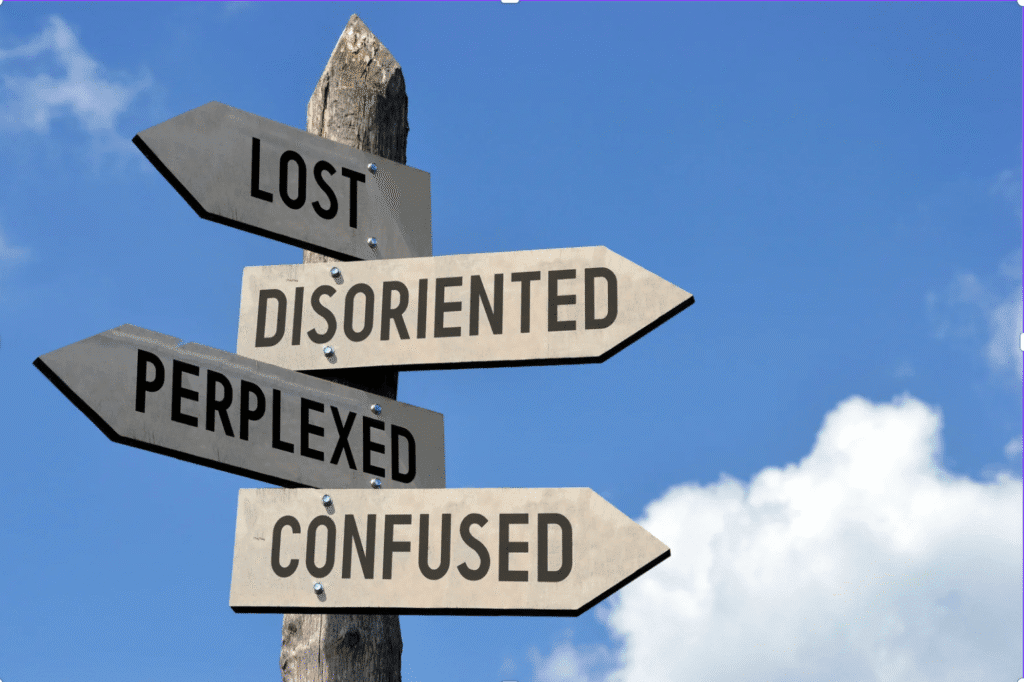

The Hidden Cost of Poor Support

It’s easy to be tempted by the lowest upfront price, but what happens when things go wrong? A CNC machine or laser cutter is a vital production tool. If it stops working, jobs can’t be completed, deadlines are missed, and reputations are put at risk.

We’ve seen companies wait weeks for a call back, or worse — be told their only option is to replace expensive parts unnecessarily. This downtime quickly costs far more than any initial saving.

On the surface, choosing the cheapest CNC router or laser cutter might look like a smart business decision. But the true cost often reveals itself after installation — when things don’t go as smoothly as promised.

When a supplier fails to provide reliable support, the impact goes far beyond the inconvenience of a machine being offline. Poor support can mean:

Lost production time – Every hour your machine is down, orders can’t be fulfilled, projects stall, and staff are left waiting.

Missed deadlines – In industries like signage, joinery, and fabrication, even a short delay can mean letting customers down and damaging hard-earned reputations.

Wasted money – Without expert advice, businesses are often told to replace parts unnecessarily, or pay inflated call-out charges for problems that could have been solved remotely.

Operator frustration – When staff don’t feel supported, confidence in the machine drops, productivity suffers, and morale can take a hit.

Lost opportunities – Time spent waiting on poor support is time that could have been used to grow, win new contracts, or take on bigger projects.

In short, a lack of dependable after-sales care doesn’t just cost money, it costs time, customers, and peace of mind. That’s why at Opus CNC we put support at the heart of everything we do.

Remember...

When comparing CNC router machines and laser cutters, it’s natural to look at specs and price. But remember: the real test of a supplier is what happens after the machine is delivered.

At Opus CNC, we’re proud that our reputation for service is just as strong as the machines we build. It’s why so many businesses across the UK now trust us to keep their production moving.

If you’d like to learn more about our CNC routers or lasers, and the support that comes with them, contact our team today on 0191 386 5303.