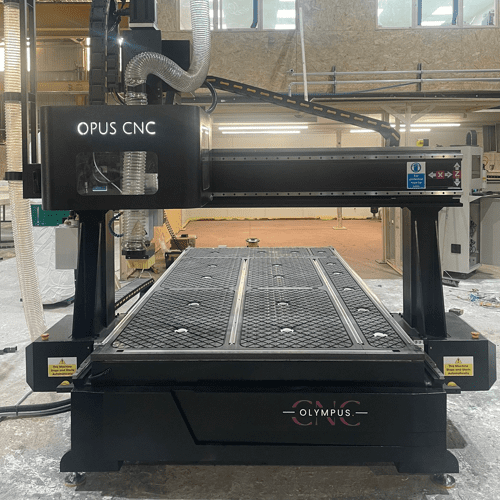

THE HOME OF

CNC ROUTERS

Industrial CNC Routers for Every Industry — UK Delivery, Installation & Training Included

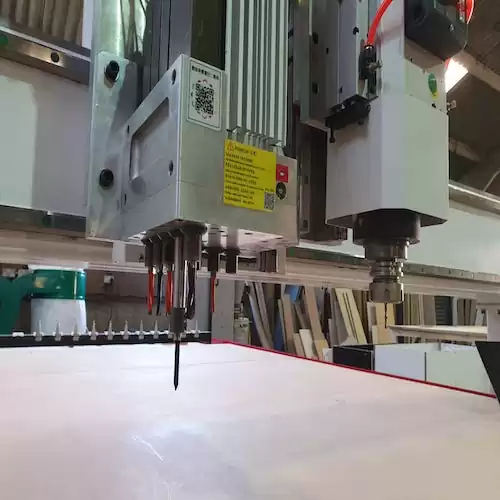

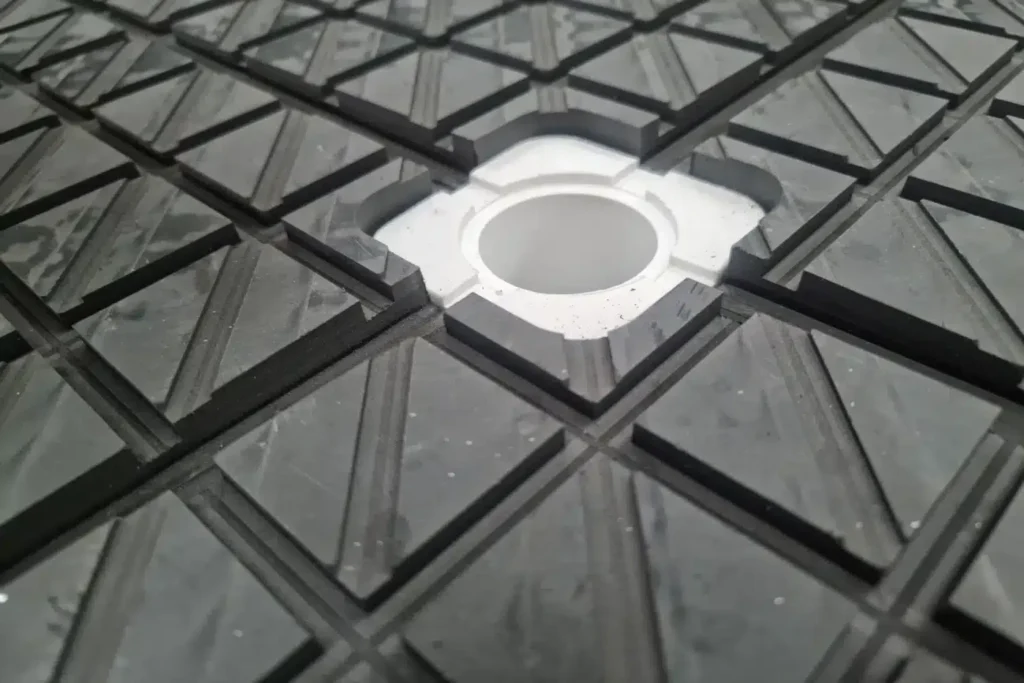

We are committed to providing cutting-edge CNC solutions that elevate your manufacturing resources to the next level. With a comprehensive range of high-performance CNC machines, including 3-axis, 4-axis, and 5-axis routers, we cater to businesses of all sizes and industries.